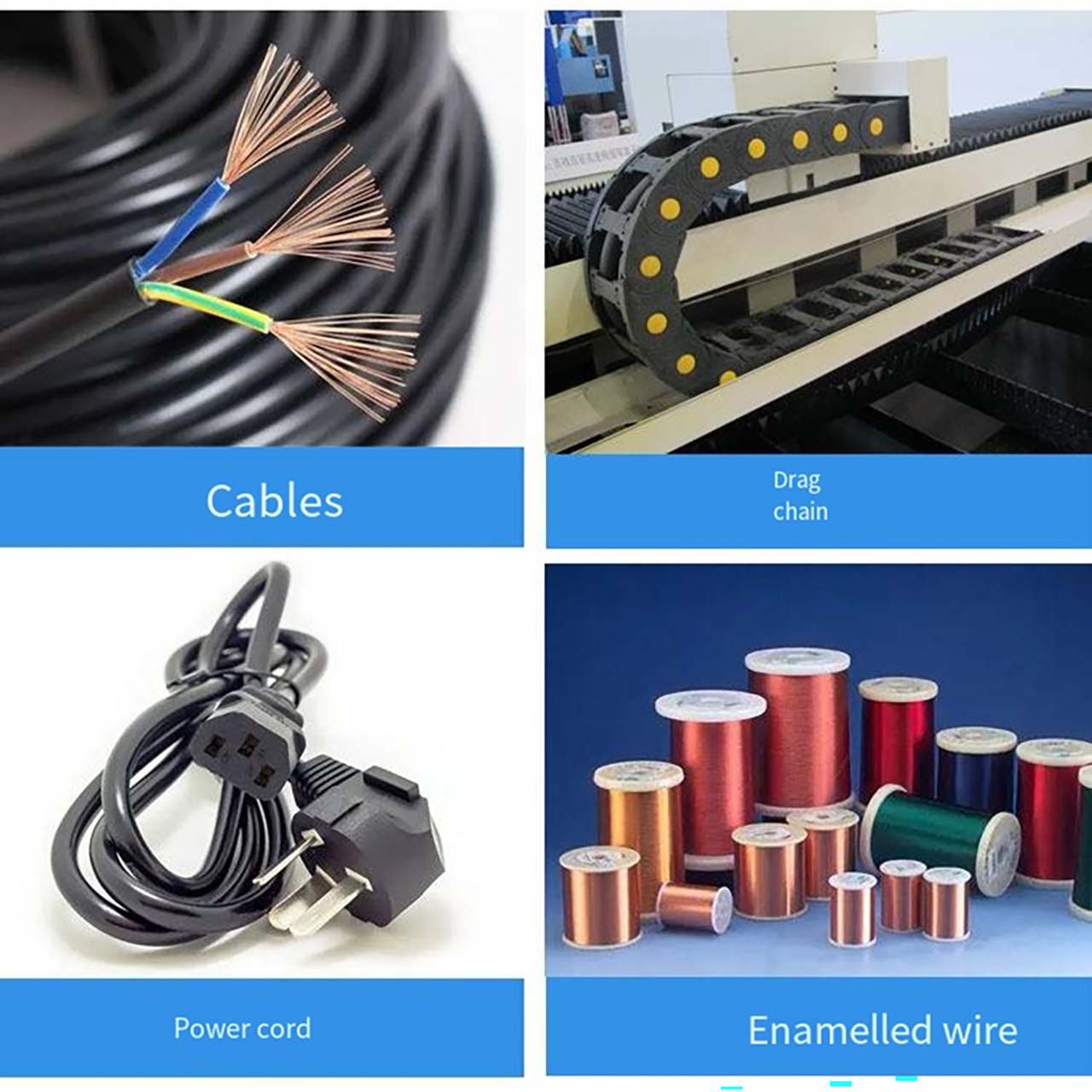

Wire drag chain bending testing machine

Main functions

U-shaped drag chain bending testing machine

1. PLC touch screen display:

Parameter settings: machine control related parameters;

Test conditions: test speed, number of tests, test stroke, control conditions, pause time during the test process, etc.;

Test monitoring: equipment operating status, such as actual speed, times, stroke, display date and time during wire testing;

2. No human supervision is required: the equipment can automatically determine whether the sample is on or off by monitoring the circuit of the sample. When it detects that the circuit is disconnected, you can choose to: continue running and issue an audible and visual warning, or stop running until manual inspection and confirmation. Continue testing again.

3. Special clamp: The bending radius can be adjusted according to the diameter of the cable and the size of the drag chain (width 40mm~150mm), and a special spacer is used in the same drag chain to limit the cable to a fixed position;

4. Online monitoring: The monitoring points are divided into 4 groups, each group has 6 pairs of interfaces, which can meet the simultaneous monitoring of 24 pairs of wires. The wiring board is installed directly in front of the workstations on both sides to facilitate the connection of sample cables. Online monitoring information can be connected to external warning signals for shutdown control.

5. The equipment can be expanded to measure conductor resistance online with multi-channel resistance monitors, and the resistance measurement data can be managed through network information through server software.

Parameters

Drag chain cable repeated bending testing machine

Model:KS-TR01

Test station: 1 station (can be customized according to customer needs)

Test method: horizontal bending, the sample is fixed in the corresponding drag chain, and the horizontal bending test is performed following the drag chain

Test space: The workstation can be installed with a drag chain width of 15mm-100mm

Maximum load-bearing: The maximum sample weight that the workstation can bear is: 15kg

Sample diameter: Φ1.0-Φ30mm

Test stroke: 0-1200mm can be set

Test line speed: 0-5.0 m/s, (0-300m/min) adjustable

Test acceleration: (0.5~20)m/s2 adjustable

Bending radius: Radius 15mm-250mm, adjustable up and down, suitable for drag chains with fixed height 30mm-500mm

Control method: touch screen control + PLC

Online monitoring: 24 pairs of monitoring interfaces, the equipment can be expanded to connect with multi-channel resistance monitors to measure conductor resistance online

Counting digits: 0-99999999 times, can be set arbitrarily

Speed range: 0~180m/min adjustable

Machine size: 1800*720*1080(mm)

Weight: 1400kg

Test lead voltage DC 24A

The maximum number of core wires that can be measured can conduct softness test of 1-50 core wires and cables.

Power supply: AC220V/50Hz