Universal Scorch Wire Tester

Application

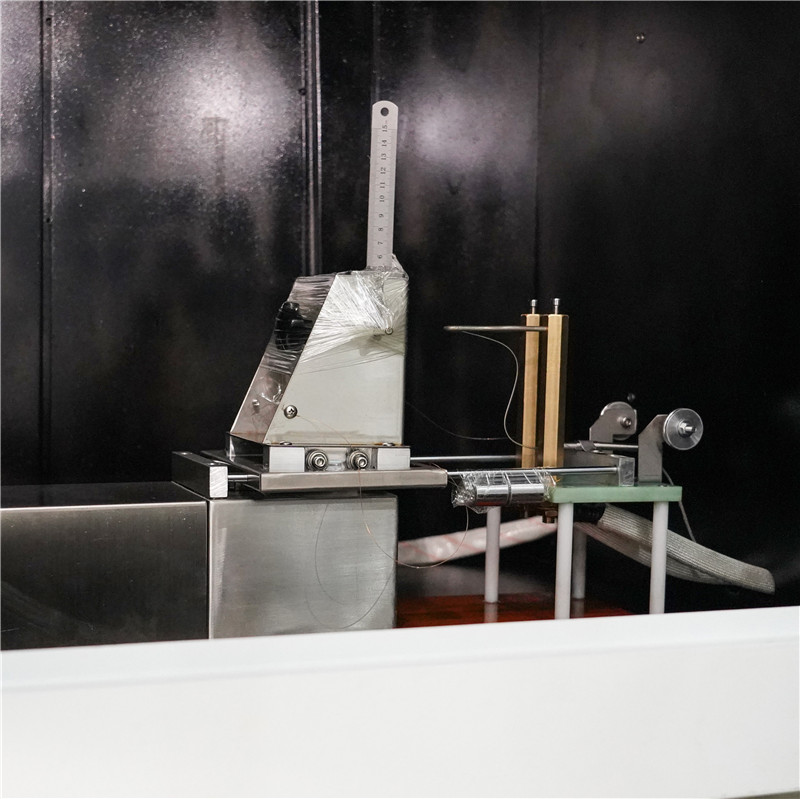

Glow burning wire testing machine

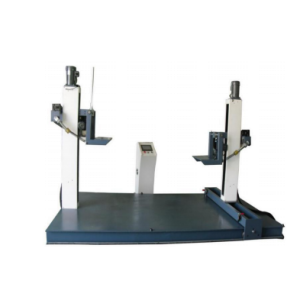

The Scorch Wire Tester has an integrated design of the test box and control part, which makes it convenient for on-site installation and debugging. The test box shell and important parts are made of stainless steel, which makes it resistant to smoke and gas corrosion. The tester uses a silicon-controlled automatic control system to automatically adjust the current, achieving precise control of the temperature. The time and temperature are displayed digitally, making it easy to observe and record. The tester is stable and reliable.

Insulating materials or other solid combustible materials that are prone to flame propagation inside the device may ignite due to hot wires or hot components. Under certain conditions, such as fault currents flowing through wires, component overload, and poor contacts, certain components may reach a certain temperature and cause nearby parts to ignite. The hot wire ignition test machine uses simulation techniques to assess the fire hazard caused by hot components or overload resistors and the thermal stress they generate in a short period of time. It is applicable to electrical and electronic equipment and their components, as well as solid electrical insulation materials or other solid combustible materials.

Auxiliary Structure

| Heating temperature | Continuously adjustable within 550-1000° ≤ range, temperature measurement accuracy ±5°c |

| Scorch Wire Time | 0.01-99S99, ±0.01S (time range adjustable) |

| ignition time | 0.01-99S99, ±0.01S (time range adjustable) Automatic recording, manual pause. |

| Flame out time |

0.01-99S99, ±0.01S (time range adjustable) Automatic recording, manual pause. |

| Scorch wire to pattern pressure | 1±0.5N, with a pressure-limiting depth of 7MM. |

| scorching wire | Φ4 nickel (%80) chromium (%20) material, made to specified dimensions |

| thermocouples | Armouring element 1.0 |

| External dimensions approx. | 1070* 650 *1150mm + exhaust cap height 200mm |

| Inner box size approx. | 780* 650 *1080mm |