Three Integrated Test Chamber

Fulfilment Criteria

GMW 14834-2013 Specification for verification and reliability testing of loudspeakers

GB/T 2423.1-2008 Test A: Low temperature test method

GB/T 2423.2-2008 Test B: High temperature test method

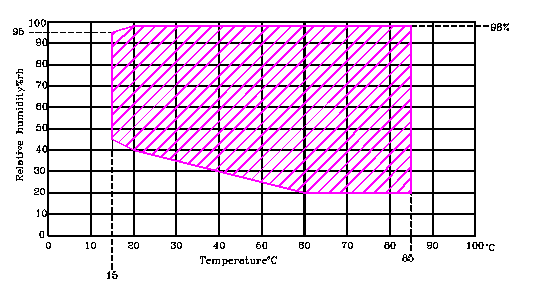

GB/T 2423.3 Test Ca: Constant damp heat test

GB/T 2423.4 Test Db: Alternating humidity and heat test

GJB 150.3A-2009 High temperature test

GJB 150.4A-2009 Low temperature test

GJB 150.9A-2009 Damp heat test

GJB 1032-90 Environmental stress screening method for electronic products

Implementation standards

Customized three-comprehensive environmental experiment box

According to GB2423.1, GB2423.2 "Electrical and Electronic Products Environmental Test Test A: Low Temperature Test Methods, Test B: High Temperature Test Methods", the products are subjected to low temperature and high temperature tests and constant temperature and heat tests. The products conform to GB2423.1, GB2423.2, GJB150.3, GJB150.4, IEC, MIL standards.

Control methods and features:

Balance temperature and humidity control system (BTHC), with P.I.D. way to control the SSPR, so that the heating and humidifying amount of the system is equal to the amount of heat and humidity loss, so it can be used stably for a long time.

Product Performance

Refrigeration/dehumidification systems

Refrigeration/dehumidification systems

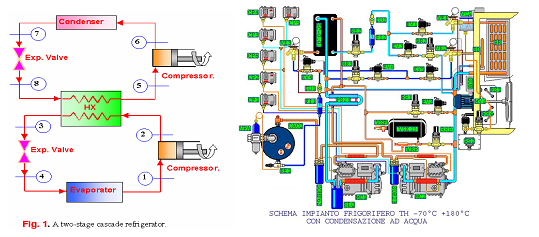

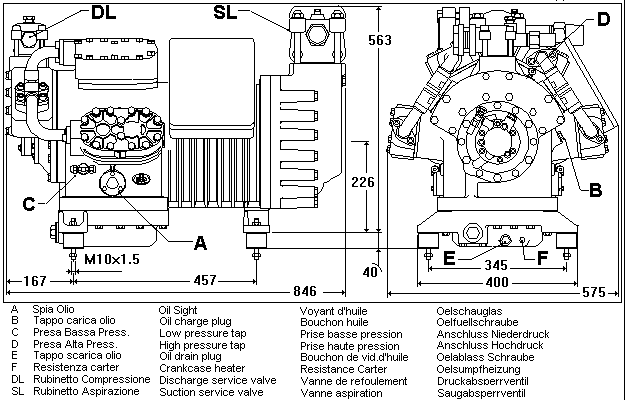

Refrigeration system and compressor: In order to ensure that the test chamber on the cooling rate and the minimum temperature requirements, the test chamber using a set of (2) Germany BITZER semi-hermetic compressor composed of binary compound refrigeration system. Compound system contains a high-pressure refrigeration cycle and a low-pressure refrigeration cycle, which connects the container for the evaporation condenser, evaporation condenser function for the low-pressure cycle of the evaporator as a high-pressure cycle of the condenser used.

The cooling system has an automatic compressor protection system that protects the compressor during cooling from high temperatures with an injection system. This system is self-regulating for the compressor cooling system.

The compressor offers the following advantages:

Improved lubrication and lower piston temperatures for greater reliability;

Streamlined case for improved gas management, reduced pressure loss and increased efficiency;

Multi-valve intake provides uniform cylinder cooling to minimise wear;

Head discharge valves provide continuous minimum discharge tube pulsation;

The new crankcase ventilation system significantly reduces the rate of oil circulation; SENTRONIC;

Provides a reliable lubrication protection system;

Multiple viewing glasses enhance serviceability and design adaptability.

Refrigeration principle: high and low refrigeration cycle are used in inverse Karo cycle, the cycle consists of two isothermal process and two adiabatic process, the process is as follows: the refrigerant is adiabatically compressed by the compressor to a higher pressure, consuming the work to make the exhaust temperature, after the refrigerant by the condenser isothermally and the surrounding medium for heat exchange heat transfer to the surrounding medium. After the refrigerant by the cut-off valve adiabatic expansion work, this time the refrigerant temperature is reduced. Finally, the refrigerant through the evaporator isothermal from the higher temperature object heat absorption, so that the temperature of the object to be cooled down. This cycle is repeated over and over again to achieve the purpose of cooling. (See figure below)

| Refrigeration working principle diagram |

| A、Dehumidification method and working principle: The dehumidification method of this test chamber adopts refrigeration condensation method. The basic principle is to control the surface temperature of the evaporator/dehumidifier of the refrigeration system below the dew-point temperature of the circulating air, so that the cooled air through the intervals below the dew-point temperature and precipitation of the water vapour contained in order to achieve the purpose of dehumidification. |

| B、Control mode: the refrigeration circuit adopts the cold control mode (energy-saving control), the test chamber in the low temperature and high temperature constant temperature test, the system according to the need to automatically determine the opening of the compressor and the size of the refrigeration capacity adjustment. Refrigeration power can be accurately controlled, precise adjustment of the size of the cooling capacity. Relative to peer manufacturers average energy saving of about 30% (refrigeration compressor work without a heater, heating refrigeration does not work).

Cooling method: air-cooled. |

| C、The cooling system has an automatic compressor protection system that protects the compressor during cooling from high temperatures with an injection system. This system is self-regulating for the compressor cooling system. |

| D、Evaporator: Finned tube heat exchanger。 |

| E、Throttling device: thermal expansion valve, capillary tube. |

| F、Refrigerant: Use environmentally friendly refrigerants R404A and R23, both with an ozone index of 0. |

| G、Refrigeration system: the main configuration adopts imported brand components, with pressure protection device and cooling device, high/low pressure sensor, the control screen can be displayed in real time. |

| H、Refrigeration and dehumidification system manufacturing process advanced: in the design of the refrigeration and dehumidification system gives full consideration to the compressor's protection measures, such as the compressor return temperature automatic adjustment and protection function, the function of the compressor's operating temperature to maintain in the normal temperature range, to avoid the compressor overcooling or overheating, in order to extend the service life of the compressor. |

| I、In the refrigeration and dehumidification system pipeline welding on the use of high-quality oxygen-free copper gas-shielded welding method, which avoids the traditional welding method caused by oxides in the inner wall of the copper tube on the refrigeration system and compressor damage. |

| J、Vibration damping measures and noise reduction:

1. Compressor: spring damping; 2. Refrigeration system: special rubber cushion overall secondary vibration damping; refrigeration system piping to increase the R and elbow way to avoid vibration and temperature changes caused by the copper pipe deformation, resulting in refrigeration system piping rupture; 3. Refrigeration chassis: the use of honeycomb special sound-absorbing sponge sound absorption. |

Product Technology Programme

Three comprehensive vibration test chambers for high and low temperature and hot and humid environments

In order to adapt to the market needs and competition, the company always carries out the "rigorous, pragmatic, pioneering, enterprising" eight-character policy, insisting that only scientific and technological innovation is the only way out of the enterprise. Adhering to this excellent idea, Dongling people after years of hard work, research and development and production of a variety of series of vibration test system, mainly air-cooled series, water-cooled series.

Water-cooled series vibration test system has a wide frequency, excellent indicators, high reliability, small footprint, easy to move, easy to operate and many other advantages. Water-cooled series vibration test system has a large thrust, strong load capacity, water-cooled mode of high efficiency. Customers can choose independently according to the actual needs.

The vibration test system is mainly used to carry out product vibration environment and shock environment test, environmental stress screening test, reliability test, can also be used for product fatigue test, in order to carry out product life assessment.

equipment working diagram

Equipment Model

|

serial number |

Main configurations |

Number |

|

1. |

stylobate |

|

|

|

(ET-70LS34445)vibration generator |

1 |

|

|

(CU-2)Cooling unit |

1 |

|

2. |

power amplifier |

|

|

|

(SDA-70W)power amplifier |

1 |

|

3. |

accessory |

|

|

|

LT1313 Horizontal slide (aluminium alloy) |

1 |

|

|

VT1313 Extension Countertop(aluminium) |

1 |

|

|

auxiliary support |

1 |

|

|

VT0606(aluminium) |

1 |

|

4. |

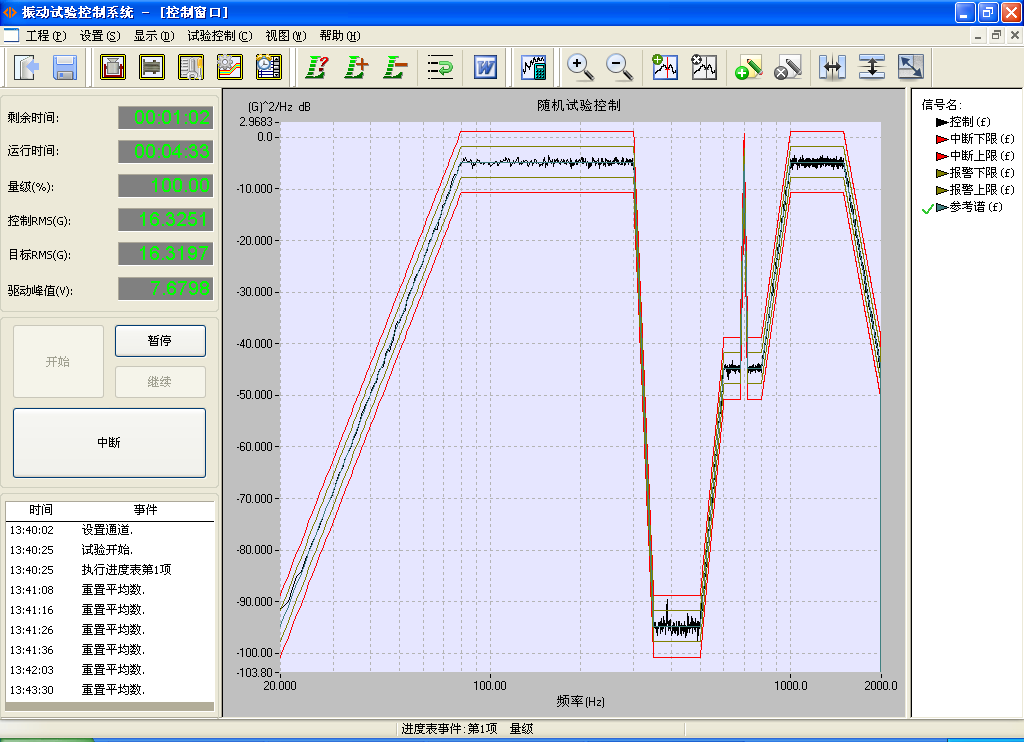

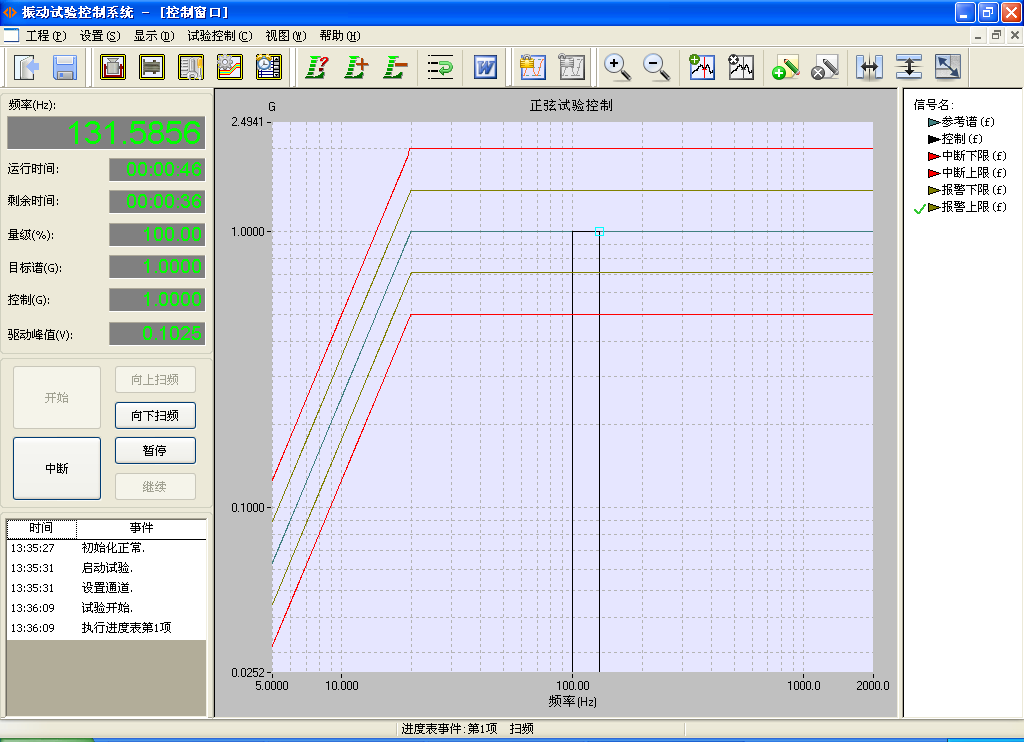

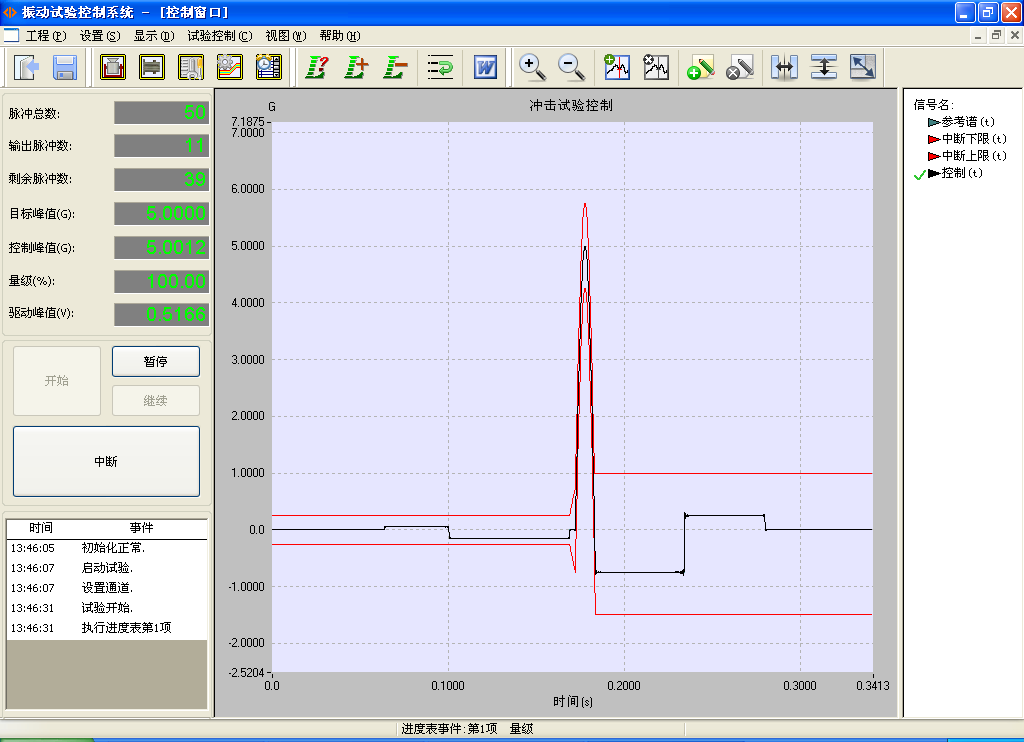

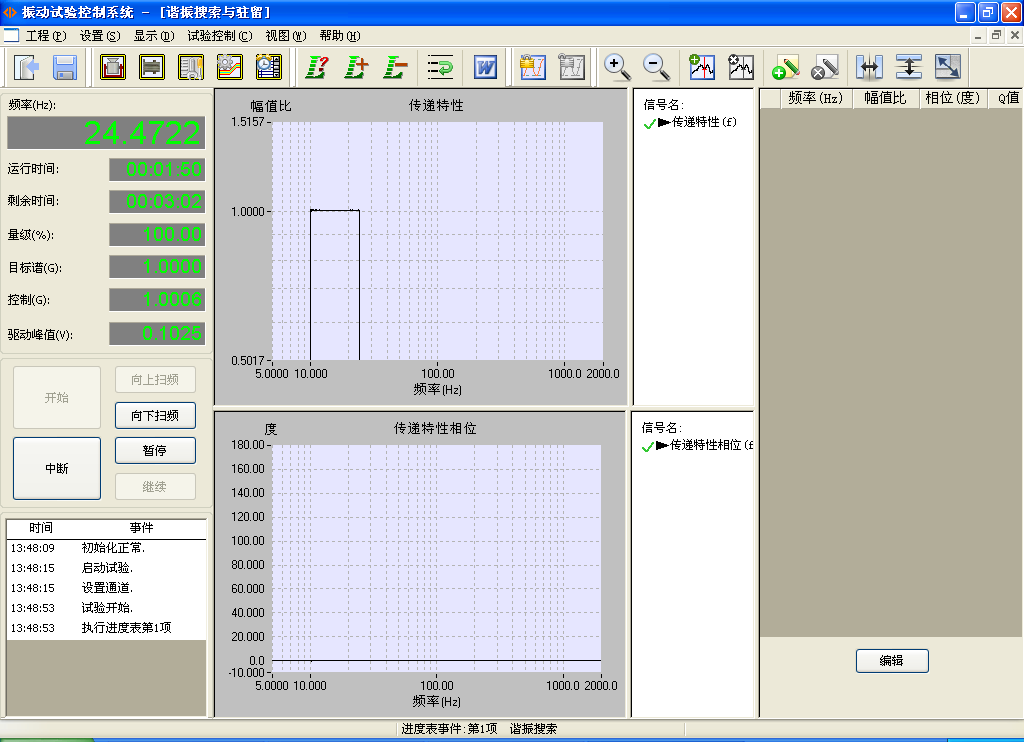

Controller ------------DYNO Vibration Control System 4 Channels |

|

|

|

Functions: sinusoidal control, resonance search and dwell, random control, typical shock control |

|

|

|

DELLComputer (with monitor) |

1 |

|

|

HP A4 inkjet colour printer |

1 |

|

|

DL Sensor (with 10m cable) |

4 |

|

|

Software package CD-ROM |

1 |

|

|

user's manual |

1 |

|

5. |

attachment (email) |

|

|

|

cable |

1 |

|

|

Triple-integrated unit (heat-insulating mat, waterlogging tray) |

1 |

|

|

Attachment Tools |

1 |

| ET-70LS4-445 table body parameters | |

| Rated sinusoidal excitation force(peak): | 70 KN |

| Rated random excitation force(rms): | 70 KN |

| shock excitation force(peak) | 140 KN |

| Frequency range: | 1~2400 Hz |

| maximum displacement(p-p): | 100 mm |

| Maximum speed: | 2 m/s |

| maximum acceleration: | 1000 m/s2 |

| First order resonant frequency: | 1800 Hz±5% |

| Maximum load: | 800 kg |

| vibration isolation frequency: | 2.5 Hz |

| Diameter of working table surface: | Ф445mm |

| Equivalent mass of moving parts: | 70kg |

| Countertop Screws: | 17×M12 |

| leakage | <1.0 M |

| Table size L×W×H | 1730×1104×1334mm(Subject to design drawings) |

| Table body mass(kg) | Ahout 4500kg |

| SDA-70W amplifier parameters | |

| Module: | IGBT |

| Individual module power: | 12KVA |

| Rated output power: | 70 KVA |

| output voltage: | 100V |

| Output Current: | 700A |

| static (in a signal) | 65dB |

| Amplifier efficiency: | Greater than 95 per cent |

| Input Impedance: | ≥10KΩ |

| Harmonic distortion (resistive loads): | <1.0%(typical value) |

| Output voltage measurement error: | ≤1% |

| Output current measurement error: | ≤1% |

| Output current crest factor: | ≥3 |

| DC stability: | Output zero drift not more than 50mv/8h |

| Frequency response: | DC~3500Hz,±3dB |

| IF Gain: | ≥80 |

| The nature of the load: | Resistive, Capacitive, Inductive |

| The degree of parallel homogeneous flow imbalance: | ≤1% |

|

Amplifier display: |

The power amplifier adopts touch screen, and the interface can display various data of the system and the operation status and fault judgement in detail. |

| System protection: | Over-displacement protection, over-current protection, overload protection, over-heat protection, over-voltage protection, under-voltage protection, phase-loss protection, cooling system protection circuit, leakage protection, drive power supply, current limiting, module pass-through, module temperature protection, etc. |

|

electromagnetic compatibility |

CE/LVD Low Voltage Directive (Safety) and CE/EMC Electromagnetic Compatibility Directive two certificates, provide the corresponding certificate. |

| CU-2 Cooling Unit Parameters | |

| Internal circulating water (distilled water) flow: | 80L/min |

| Internal circulating water (distilled water) pressure: | 1Mpa |

| External circulating water (tap water) flow: | 160L/min |

| External circulating water (tap water) pressure: | 0.25~0.4Mpa |

| Distilled water requirements | Water hardness 30ppm, PH7~8, conductivity 1Us/cm |

| Water pump power | Internal circulation 8KW, external circulation 4KW |

| LT1313 Horizontal Slide Table | |

| Material: | aluminium |

| Countertop size: | 1300×1300 mm |

| Upper frequency | 2000Hz |

| Countertop weight: | About 298kg |

| VT1313 Vertical Expansion Table | |

| Material: | aluminium |

| Countertop Dimensions: | 1300×1300 mm |

| Upper Frequency: | 400Hz |

| Countertop weight: | About 270kg |

| In conjunction with auxiliary supports and guides | |

| VT0606 Vertical Expansion Table | |

| Material: | aluminium |

| Countertop Dimensions: | 600×600 mm |

| Upper Frequency: | 2000Hz |

| Countertop weight: | Ahout 57kg |

| System working environment requirements | |

| environmental conditions | Temperature: 5-40°C, humidity: 0-90%, no condensation |

| power supply | 3-phase 4-wire 380VAC±10% 50Hz 70kVA |

| Compressed air requirements | 0.6 Mpa |

| Laboratory grounding resistance | ≤4 Ω |

| *Connecting cables come standard with a length of 10m. | |

Main technical parameters

Temperature humidity and vibration three comprehensive experimental chamber

System features

The vibration controller is designed with the most advanced distributed system structure system in the world, and its core adopts the latest 32-bit floating-point DSP processor of TI Company. The system uses low-noise design technology, floating-point digital filtering technology and 24-bit resolution ADC/DAC. vibration control using adaptive control algorithms, vibration control system technology performance to a new level. The vibration controller features are as follows:

High performance-price ratio and reliability

Hardware adopts modularisation and low-noise design technology.

High control accuracy and wide dynamic range

Adopting dual DSP parallel processing structure, 24-bit resolution ADC/DAC, together with high-precision floating-point digital filtering and low-noise design technology, the control system has high dynamic range and control accuracy.

The input methods are flexible and varied.

In addition to the direct input of voltage signals, the system has a built-in ICP constant current source and charge amplifier for direct connection to ICP-type and charge-type accelerometers.Windows-based application software for easy operation。

Control system by the DSP to achieve closed-loop control, so that the PC software is independent of the control loop, the real real realisation of the Windows multi-tasking mechanism and graphical interface, the user is convenient to operate, the display form is rich.

Automatic generation of Microsoft Word test reports

During and after the test, Microsoft Word test reports can be generated automatically or manually, with user-defined report contents.

Complete control functions

Sine, Random, Classical Shock, Resonance Search & Dwell and its functions can be extended according to the user's requirements.。

2)System Performance ,

The vibration controller is a high-performance vibration controller, the control software runs under Windows, the PC software is responsible for user parameter setting, running manual control, and display, etc. The closed-loop control is realised by the DSP in the control box, which really realises the Windows multi-tasking mechanism and is easy for users to operate. Reasonable structure and low-noise design technology ensure that the system has a high control dynamic range and control accuracy.

Input

Number of input channels: 4 synchronised input channels.

Input impedance: greater than 110 k.

Maximum voltage input range: ±10V.

Maximum charge input range: ±10000 PC.

Signal-to-noise ratio: greater than 100 dB.

Analogue/Digital Converter (ADC): 24-bit resolution, dynamic range: 114 dB, maximum sampling frequency 192 KHz.

Input Interface: Three selectable inputs: voltage, ICP and charge.

Circuit characteristics: Input interface built-in ICP constant current source and charge amplifier. Two ranges of 10V/1V and AC/DC coupling are available. Analogue anti-alias filter.

Number of output channels: 2 output channels.

Output signal type: voltage signal.

Maximum output voltage range: 10V.

Output impedance: less than 30 .

Maximum output current: 100mA.

Amplitude accuracy: 2mV .

Digital/Analogue Converter (DAC): 24-bit resolution, dynamic range: 120dB, maximum sampling frequency 192KHz.

Circuit characteristics: analogue anti-alias filter; output protection circuit.

| Machine features: |

| 1、Shell material: shell & 1.2mm steel plate surface spraying. |

| 2、Studio material: the internal experimental space consists of &1.2mm after SUS304 stainless steel plate. Seams are fully welded and impervious to steam. |

| 3、Thermal insulation material: high fireproof grade thermal insulation material (glass wool + polyurethane foam board), with good thermal insulation effect, to ensure that the outer surface of the test box, the inner wall of the studio, the outer surface, the door seams, seams, lead holes will not appear any frost or condensation phenomenon. |

| 4、Internal Lighting: 2x 25W low voltage moisture proof lighting with control switch on the external control panel of the box. |

| 5、 Observation Window: Doors are supplied with a tough glazed observation window with internal heater, measuring 400 (W) x 500 (H) mm. the box observation window has an electronic heater on the glass surface to prevent condensation and frost. |

| 6、Door: Net size of the door aperture (mm): 750 x 750 (width x height), 36V self-temperature heating tape is pre-buried around the observation window and door frame. The opening of the heating tape can be opened automatically by the equipment according to different operating conditions to ensure that the door frame and the observation window of the door do not frost and condensation in the low temperature environment of the equipment. The opening degree of the door is ≥120℃. |

| 7、Seal strip: imported high-quality silicone rubber material, high and low temperature aging resistance, not easy to deformation, used for the sealing of the box door and the box, to ensure that the studio and the box outside no air convection, that is, no cold / heat exchange. |

| 8、Insulation resistance: the insulation resistance between each wiring device, between the wiring device and the wall of the test box is not less than 200 MΩ. |

| 9、Internal structure of the box: a single structure that includes all the systems necessary for the work of the box. The external frame consists of high-quality steel sheets, which are externally primed and coated with high-quality primers and coatings. |

| 10、External structure coating: electrostatic spraying, greyish-white in colour. |

| 11、Test hole: 1 on the left side of the box Φ 100mm lead hole, the position of the hole is determined by the user. Lead hole with cover and soft plug. |

| 12、Load capacity: 120kg. |

| 13、Drainage system: the bottom of the box body has a sink and drainage holes to ensure smooth drainage and can empty all the water. It can effectively prevent the condensate from leaking into the electromagnetic vibration table. |

| 14、Pressure balancing system: the chamber is equipped with a pressure balancing system (device), when the internal pressure of the chamber is too high or too low, the system will automatically open. When the chamber is warming up, cooling down, constant test studio and the outside air pressure is basically the same. There will be no frost at low temperature. |

| 15、Internal gas circulation: High-power fan driven by an external motor with stainless steel shaft. |

| 16、Gas conditioning unit:There is a gas conditioning line (duct) on the rear wall of the box. It includes the following components:

- Cooling exchanger - Heating exchanger - Humidification entry line - Dehumidifying evaporator - Recirculating fan for conditioned air - Temperature and humidity sensors. Before entering the chamber, the thermally conditioned air flows into the air duct and passes through the various links mentioned above. |

| 17、Heating system: Nickel-cadmium alloy electronic heater |

| 18、Humidification system: low pressure steam generator with protective electronic heater. |

| 19、Humidification water: directly connected to the softened tap water (equipment with water softening device). |

| 20、Dehumidification system: Light-tube dehumidifying evaporator connected to the cooling system. |

| 21. Humidity Control:The test chamber adopts the Swedish ROTRONIC capacitive electronic humidity sensor to set and measure the relative humidity directly in RH%. The humidity is adjusted from the absolute humidity parameter in the air by means of a "conversion algorithm" in the control software. This allows for extremely precise control. |

| 22.Control panel and unit location: box and unit as a whole. |

| 23. Noise: 75db, measured in an open space, 1 metre from the front of the unit. |

| 24. Safety protection devices: Independent ultra-high and low temperature alarm;

Fan overheating alarm; Fan overcurrent alarm; Circulating cooling water shortage alarm; Refrigeration compressor overheating alarm; Refrigeration compressor overpressure/oil shortage alarm; Compressor exhaust temperature protection Alarm for power supply phase shortage, phase sequence and over-under-voltage; Humidifier fault protection; Leakage, short circuit protection; Three-colour indicator: three-colour sound and light alarm is installed on the top of the equipment, which can show three states of equipment running, stopping and alarming. |

|

Vertical and horizontal vibration and box coupling |

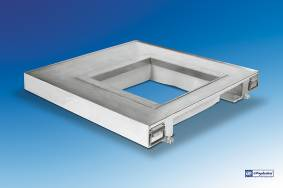

| 1. Box/shaker coupling base plate: Specialised removable base plate with holes to accommodate vertical + horizontal shakers. Silicone gaskets are provided at the interface between this plate and the shaker. The silicone gasket provides a seal between the shaker and the base plate. Special mechanical clamps are used to secure the removable base plate to the box structure. |

| 2. Box base plate: Three special movable base plates to connect the box:

One for the bottom plate with holes, to do vertical impact vibration when used; (can be extended to do impact collision use. (For details, see the parameters of the impact collision table) A bottom plate with square holes, to be used in conjunction with the horizontal sliding table; A blind plate, not for vibration use. |

| Silicone sealing gaskets are used to provide a seal between the shaker and the base plate as well as between the sliding base plate and the cabinet.Special mechanical clamps are provided to secure the removable base plate to suit the cabinet construction.

A condensate drain on the shaker base plate prevents condensate from flowing into the shaker. |

| Motion mode: |

| 1、Movement mode: the whole test chamber adopts the horizontal movement (left and right direction) along the electric way of the track; the bottom of the box is equipped with track wheels, which can be slid on the track, and it is convenient for the box to be separated from the shaking table or to be used separately. |

| 2, lifting mode: studio box adopts electric screw way up and down, that is, when lifting, only the studio lifting and box unit does not move. The refrigeration pipeline between the studio box and the unit adopts our unique soft connection technology, and the key components are imported products, so the reliability of the soft connection is quite high. The application of this technology reduces the weight of the equipment, the overall sense of the equipment is greatly enhanced, and lifting freely, easy to operate, high reliability. |

| 3、Through the up and down lifting of the workshop box and the left and right movement of the whole machine, it can be connected with the vertical extension table of the vibration table, connected with the horizontal sliding table or be in the idle station, and realise the accurate positioning of the three working stations. |

| 4、Power cord is soft, can be swung left and right at a distance of not less than 2M |