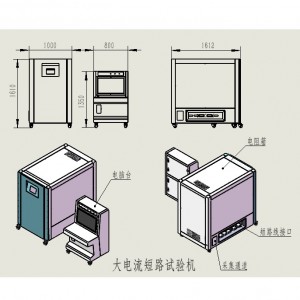

Simulation of high altitude low pressure testing machine

Test Purpose

Battery Simulation High Altitude and Low Voltage Testing Machine

The objective of this test is to ensure that the battery does not explode or catch fire. Furthermore, it should not emit smoke or leak, and the battery protection valve should remain intact. The test also evaluates the performance of other electronic and electrical products under low voltage conditions, ensuring that they function properly and are not damaged.

Standard Requirements

Simulated high-altitude low-pressure test chamber

Following the specified test method, the battery is fully charged and then placed in a vacuum box at a temperature of 20°C ± 5°C. The pressure inside the box is reduced to 11.6 kPa (simulating an altitude of 15240 m) and maintained for 6 hours. During this time, the battery must not catch fire or explode. Additionally, it should not exhibit any signs of leakage.

Note: The ambient temperature of 20°C ± 5°C is regulated to meet the standard requirements.

| Inside box size | 500(W)×500(D)×500(H)mm |

| Outer box size | 800(W)×750(D)×1480(H)mm subject to the actual object |

| compartment | The inner box is divided into two layers, with two distribution boards |

| visual window | Door with 19mm toughened glass window, specification W250*H300mm |

| Inner box material | 304# stainless steel industrial plate thickness of 4.0mm, internal reinforcement treatment, vacuum does not deformation |

| Outer case material | Cold rolled steel plate, 1.2mm thick, powder coating treatment |

| Hollow filler material | Rock wool, good thermal insulation |

| Door sealing material | High temperature resistant silicone strip |

| caster | Installation of movable brake casters, can be fixed position, can be pushed at will |

| Box structure | One-piece type, operating panel and vacuum pump are installed under the machine. |

| Evacuation control method | Adopting E600 7-inch touch screen instrument, the whole process is fully automatic, after the product is put into the vacuum can be started. |

| control mode | Parameters such as upper vacuum limit, lower vacuum limit, holding time, end pressure relief, end alarm, etc. can be set arbitrarily. |

| tightness | The doorway of the machine is sealed with high-density silicone sealing strips. |

| Vacuum induction method | Adoption of diffuse silicon pressure sensors |