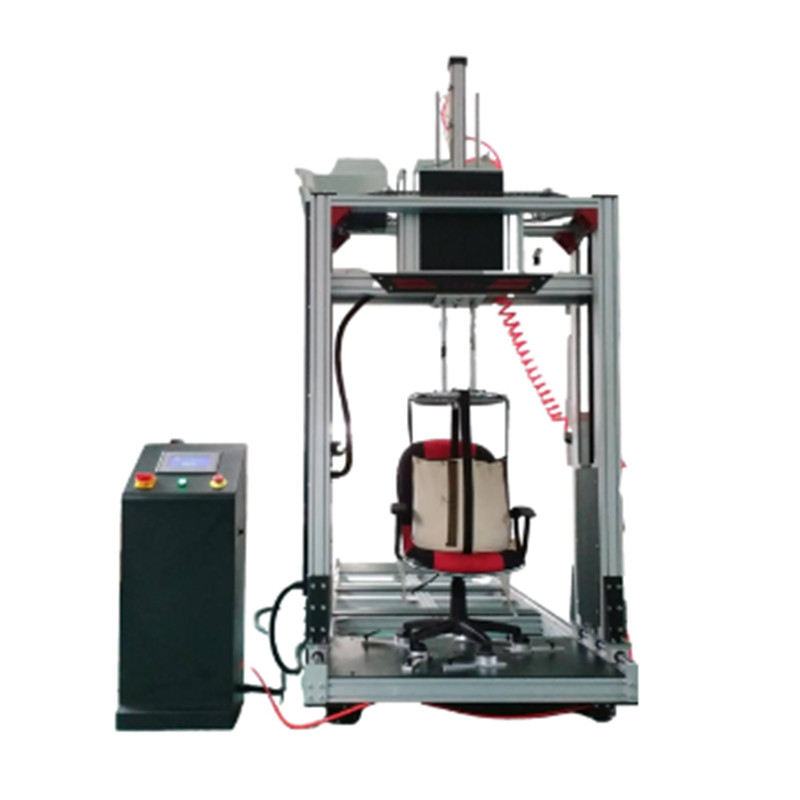

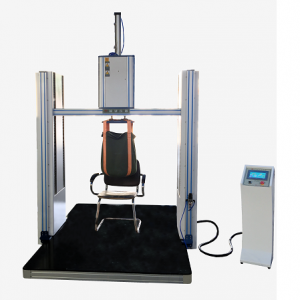

Office seat vertical impact testing machine

Application

By designing a reasonable test scheme, the deformation and durability of the chair under different impact forces can be detected, so as to evaluate the service life and structural stability of the chair. In the test, the seat surface of the chair should be subjected to two forces: horizontal impact and vertical impact. The horizontal impact force simulates the impact when the chair is pushed or moved, and the vertical impact force simulates the impact when the chair is sitting. The impact testing machine will carry out multiple impact tests on the chair to assess its deformation and durability under different impact forces. Through the testing of the office chair seat surface impact testing machine, manufacturers can understand the performance of the product during use and make corresponding improvements.

| Product name | Office seat vertical impact testing machine |

| Overall dimension | 840*2700*800mm(L*W*H) |

| Cylinder stroke | 0~300mm |

| Register | 1 6-bit, power-off memory, output control Impact 100000 times + static pressure left corner 20000 times + static pressure right corner 20000 times |

| Impact sand bag (weight) | diameter 16 inches, weight 125 pounds standard sand bag |

| Static pressure module (weight) | diameter 8 inches, weight 165 pounds briquette |

| Power source | 220VAC 1A |

| Shutdown mode | When the number of test times is stopped, the specimen is damaged or the deformation is too large, the machine will automatically stop and give an alarm |

| Impact speed | 10~30 times/min or specify 10~30CPM |

| Static pressure speed | 10~30 times/min or specify 10~30CPM |

| Crossbar height | 90~135cm |

| Impact test | 16 inches in diameter and 125 pounds sandbag 1 inch higher than the chair surface 1 inch above the chair surface at a speed of 10~30CPM to impact the chair surface 100,000 times |