Introduction: The Role of Temperature and Humidity Chambers in Quality Control

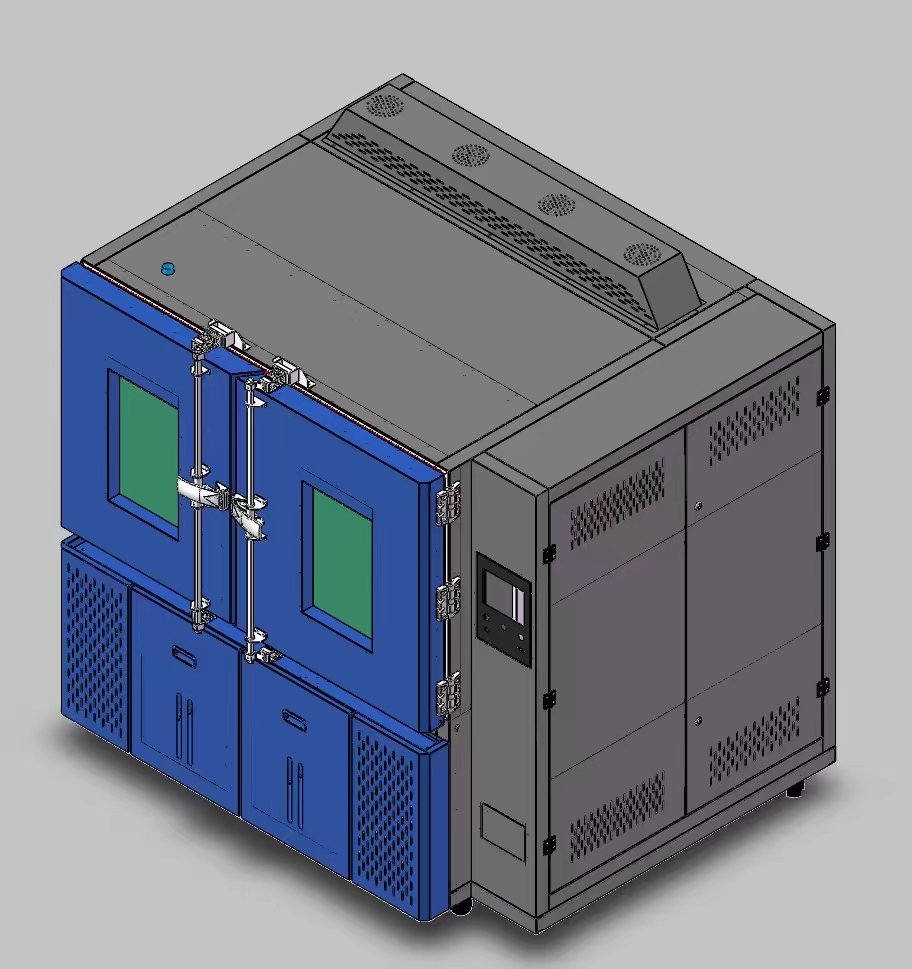

A temperature and humidity chamber, also known as an environmental test chamber, plays a vital role in this process.

These chambers are designed to simulate extreme environmental conditions, helping manufacturers and testing labs verify product performance, durability, and compliance with industry standards.

From electronics to pharmaceuticals, these chambers are indispensable tools for quality control testing and industrial testing.

Core Functions of Temperature and Humidity Chambers

Precision Control of Environmental Conditions

The primary function of a temperature and humidity chamber is to create a controlled environment where temperature and humidity can be precisely adjusted. This includes:

- Temperature Range: Ranging from sub-zero levels to extreme heat, typically between -70°C and 180°C.

- Humidity Range: Humidity control from near-zero (dry) to saturated conditions, often between 20% RH and 98% RH.

- Accuracy: Advanced models ensure highly stable conditions with deviations as low as ±2°C or ±3% RH.

Flexible Testing Capabilities

These chambers can replicate real-world scenarios such as rapid temperature shifts, long-term exposure to humidity, and cyclic environmental changes.

Features like programmable controllers and data logging enhance usability for repeated testing protocols.

Application Areas: From Factories to Third-Party Labs

1. Factory Quality Control

In manufacturing, temperature and humidity chambers ensure raw materials and finished products meet strict quality standards. For example:

- Electronics: Testing circuit boards against thermal stress and moisture intrusion.

- Automotive: Evaluating the endurance of components like tires or dashboards in extreme climates.

2. Third-Party Testing Laboratories

Independent testing labs use environmental test chambers to validate compliance with industry certifications, such as ISO or MIL-STD.

Walk-in chambers, in particular, are highly valued for testing:

- Large batches of products, such as packaged goods or textiles.

- Oversized items like machinery or aerospace components.

Walk-In Chambers: Unique Use Cases

A walk-in chamber offers ample space for large-scale product evaluations or simultaneous testing of multiple items. These chambers are critical for industries requiring bulk testing under consistent environmental conditions.

Choosing the Right Temperature and Humidity Chamber

Selecting the ideal chamber depends on the specific needs of your operation. Consider the following:

- Testing Requirements: Define temperature and humidity ranges, testing volume, and accuracy needs.

- Customization: Does your testing involve unique conditions or standards? Custom solutions can meet these demands effectively.

- Space and Scale: A walk-in chamber is optimal for high-volume or oversized product testing.

Kesionots’ Customization Advantage

At Kesionots, we specialize in tailoring solutions to fit diverse industrial and laboratory requirements. Our chambers offer:

- Flexible Configurations: Choose dimensions, temperature ranges, and advanced controls.

- Compliance: Designed to meet industry-specific standards like ISO, CE, or CNAS requirements.

- Innovative Features: Energy-efficient designs, user-friendly interfaces, and automated testing capabilities.

Explore Kesionots Walk-In Constant Temperature and Humidity Rooms

Conclusion: Elevate Your Testing with Kesionots

Whether you’re in a factory quality control department or managing a third-party testing lab, a temperature and humidity chamber is an essential tool for ensuring product reliability and compliance.

Kesionots takes pride in offering customized solutions that address specific testing needs, including walk-in chambers for large-scale applications.

Contact us today to learn how Kesionots can provide the perfect environmental testing chamber for your business. Let us help you achieve unmatched precision and reliability in your testing processes.

Post time: Dec-03-2024