-

Falling ball impact testing machine

Impact testing machine is suitable for impact strength testing of plastics, ceramics, acrylic, glass, lenses, hardware and other products. Comply with JIS-K745, A5430 test standards.This machine adjusts the steel ball with a specified weight to a certain height, makes the steel ball fall freely and hits the product to be tested, and determines the quality of the product to be tested based on the degree of damage.

-

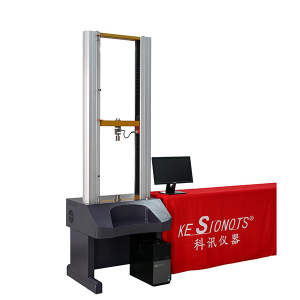

Computerised Single Column Tensile Tester

Computerized tensile testing machine is mainly used for mechanical property test of metal wire, metal foil, plastic film, wire and cable, adhesive, artificial board, wire and cable, waterproof material and other industries in the way of tensile, compression, bending, shearing, tearing, peeling, cycling and so on. Widely used in factories and mines, quality supervision, aerospace, machinery manufacturing, wire and cable, rubber and plastic, textile, construction and building materials, home appliances and other industries, material testing and analysis.

-

Wire bending and swing testing machine

Wire bending and swing testing machine, is the abbreviation of swing testing machine. It is a machine that can test the bending strength of plug leads and wires. It is suitable for relevant manufacturers and quality inspection departments to conduct bending tests on power cords and DC cords. This machine can test the bending strength of plug leads and wires. The test piece is fixed on a fixture and then weighted. After bending to a predetermined number of times, the breakage rate is detected. Or the machine automatically stops when power cannot be supplied and the total number of bends is checked.

-

Three-axis Electromagnetic Vibration Test Table

Three-axis series electromagnetic vibration table is an economic, but ultra-high cost performance of a sinusoidal vibration test equipment (function function cover fixed frequency vibration, linear sweep frequency vibration, log sweep frequency, frequency doubling, program, etc.), In the test chamber to simulate the electrical and electronic products in the transportation (ship, aircraft, vehicle, space vehicle vibration), storage, the use of the process of vibration and its impact, and assess its adaptability.

-

Drop testing machine

The drop testing machine is mainly used to simulate the natural drop that unpackaged/packaged products may be subjected to during handling, and investigate the ability of products to resist unexpected shocks. Usually the drop height is based on the weight of the product and the possibility of falling as a reference standard, the falling surface should be a smooth, hard rigid surface made of concrete or steel

-

Package Clamp Force Testing Equipment Box Compression Tester

Clamping force test equipment is a kind of test equipment used to test the tensile strength, compressive strength, bending strength and other properties of materials. It is used to simulate the impact of the clamping force of the two cleats on the packaging and goods when the clamping car is loading and unloading the packaging, and evaluate the clamping strength of the packaging, which is suitable for the finished packaging of kitchenware, furniture, home appliances, toys, etc. The clamping force testing machine usually includes a testing machine, fixtures and sensors.

-

KS-RCA01 Paper tape abrasion resistance testing machine

The RCA wear resistance meter is used to quickly evaluate the wear resistance of surface coatings such as mobile phones, automobiles, equipment, and plastic products such as surface plating, baking paint, silk screen printing, and pad printing. Use RCA special paper tape and apply it to the surface of the product with a fixed weight (55g, 175g, 275g). A fixed-diameter roller and a fixed-speed motor are equipped with a specific counter.

-

Permanent compression deflection tester

1、Advanced factory, leading technology

2、Reliability and applicability

3、Environmental protection and energy saving

4、Humanization and automated system network management

5、Timely and perfect after-sales service system with long-term guarantee.

-

Double hammer electric friction testing machine

1、Advanced factory, leading technology

2、Reliability and applicability

3、Environmental protection and energy saving

4、Humanization and automated system network management

5、Timely and perfect after-sales service system with long-term guarantee.

-

Double hammer electric leather friction testing machine

1、Advanced factory, leading technology

2、Reliability and applicability

3、Environmental protection and energy saving

4、Humanization and automated system network management

5、Timely and perfect after-sales service system with long-term guarantee.

-

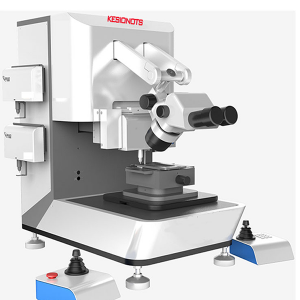

Multi-function push and pull testing machine

KS-HT01A multi-function push and pull testing machine should be widely used in LED packaging testing, IC semiconductor packaging testing, TO packaging testing, IGBT power module packaging testing, optoelectronic components packaging testing, automotive field, aerospace field, military products testing, testing institutions and various types of colleges and universities testing and other applications.

-

Tensile Testing Machine

Computer tensile testing machine is mainly used for metal wire, metal foil, plastic film, wire and cable, adhesive, man-made board, wire and cable, waterproof materials and other industries of tensile, compression, bending, shearing, tearing, stripping, cycling and other ways of mechanical properties test. Widely used in factories and mining enterprises, quality supervision, aerospace, machinery manufacturing, wire and cable, rubber and plastic, textile, construction materials, household appliances and other industries of material inspection and analysis.

Mechanics

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

-

Top