Kexun Battery Needling and Extruding Machine

Application

1.Installation of lighting tube, outside the studio can clearly see the situation; needling / extrusion speed 10 ~ 80mm / s can be adjusted; - Needling / extrusion force value

2.The needling/extrusion force values can be set at any customised level to meet different standard requirements. Wire coat metal fire pipe, effectively prevent the battery test process of ignition and combustion phenomena; separation of control and test box with form, available at 1~2 meters operation, be safe.

Squeeze: The test cell is squeezed in two planes, and a squeezing pressure of about 13KN is applied through a vise or a hydraulic arm with a piston diameter of 32mm, the squeezing continues until it rises, and once the maximum pressure is reached, the squeezing is lifted.

Needling: The test shall be carried out at an ambient temperature of 20℃±5℃, the battery connected with a thermocouple (thermocouple contacts are fixed on the surface of the battery) is placed in a fume cupboard, and a non-corrosive rust-free steel needle with a diameter of 2-8mm is used to pierce the center of the largest surface of the battery at a speed of 10mm/s-40mm/s and held for an arbitrary period of time. center of the largest surface of the cell at a speed of 10mm/s-40mm/s and hold it for an arbitrary period of time.

Application

| Squeeze Indicator: | |

| controllers | 7-inch touch screen |

| Test area space | 250mm wide x 300mm deep |

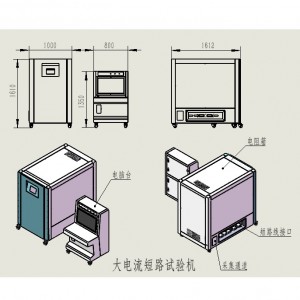

| Outer box size | Approx. 750*750*1800mm (W*D*H) subject to actual size |

| drive method | motor drive |

| Strength range | 1~20kN (adjustable) |

| Force Measurement Accuracy | 0.1% |

| unit conversion | kg, N ,lb |

| Squeeze Stroke | 300mm |

| Force value display | PLC touch screen display |

| Battery Squeeze Head | Standard extrusion head, area ≥ 20cm². |

| Inner box material | Stainless steel 1.5mm thick |

| Outer case material | 1.2 mm thick A3 cold plate with lacquered finish |

| safety device | The back side of the box is designed with air vent and pressure relief device 250*200mm, the box is equipped with lighting |

| viewing window | 250x200mm two-layer vacuum toughened glass viewing window with explosion-proof grill |

| exhaust vent | The back of the box is equipped with a high temperature exhaust fan and reserved exhaust pipe interface φ150mm.

The exhaust fan will turn on and work immediately after the power is turned on. |

| box door | Single door, left opening |

| Box door switch | Open-on-disconnect threshold switch ensures no misuse and personnel safety. |

| caster | Four universal castors underneath the machine for free movement. |

| Needlepoint Indicator: | |

| steel needle | Φ3mm/φ5mm high-temperature resistant tungsten steel needle, length 100mm (can be specified) 2pcs each. |

| Needle Stroke | 200mm |

| unit conversion | Kg、N 、lb |

| Needling speed | 10 ~40mm/s (adjustable) |

| Needlepoint force value | 1~300Kg |

| Force value display | PLC touch screen display |

| drive method | Motor control, adjustable speed |