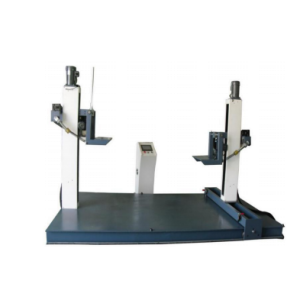

Drop testing machine

Drop testing machine:

Application: This machine s designed to test the damage caused to product packaging by drops and to assess the impact strength during transport. Drop test machine adopts brake motor through the chain drive, driven by the drop arm reach down, drop height using digital height scale, drop height precision, display intuitive, easy to operate, drop arm lifting and lowering stable, drop angle error is small, this machine is suitable for manufacturers and quality inspection departments.

| Item | Specification |

| Display method | Digital height display (optional) |

| Drop height | 300-1300mm/300~ 1500mm |

| Maximum specimen weight | 80kg |

| Maximum specimen size | (L × W × H)1000×800×1000mm |

| Drop panel area | (L × W)1700×1200mm |

| Bracket arm size | 290×240×8mm |

| Drop error | ± 10mm |

| Drop plane error | <1° |

| External dimensions | (L × W × H)1700 x 1200 x 2015MM |

| Control box dimensions | (L × W × H)350×350×1100mm |

| Machine weight | 300kg |

| Power supply | 1∮ ,AC380V,50Hz |

| Power |

8000W |

Precautions and maintenance:

1. Each time the test is completed, shall drop the drop arm down, so as not to long reset the drop arm to pull the spring deformation, affecting the test results, each time before the drop, please resume the position of the motor stops rotating before pressing the drop button;

2. The new machine to the factory installation is completed, must be in the sliding round rod at the appropriate low concentration of oil, is strictly prohibited to join the rust oil or high concentration of oil and the accumulation of species with corrosive oil.

3. If there is too much dust at the oiling place for a long time, please lower the machine to the low part, wipe the previous oil, and then re-machine oiling;

4. Falling machine is impact mechanical equipment, the new machine is used too 500 times or more, the screws must be tightened to avoid failure.