High Current Battery Short Circuit Testing Machine KS-10000A

Product Description

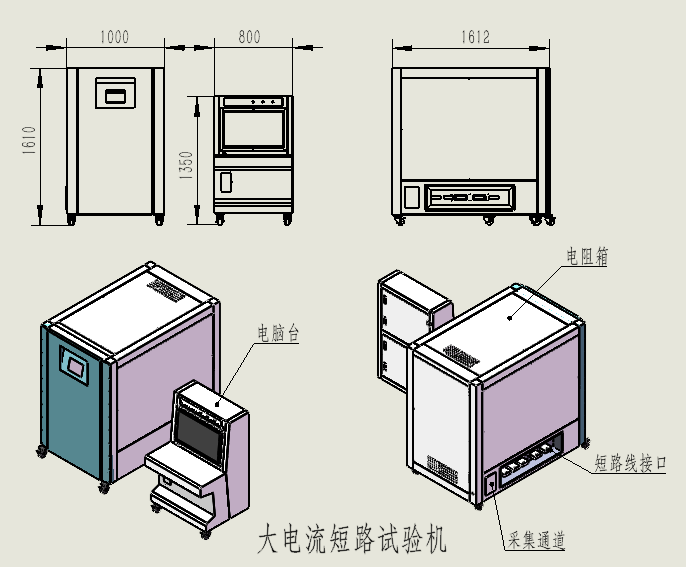

Appearance reference drawing (specifically, the actual object shall prevail)

1. Use high conductivity copper as a large current carrier during short circuit, and use a high-strength vacuum switch for short circuit (non-vacuum box);

2. Short circuit trigger (high-intensity vacuum switch opens and closes to perform short circuit) to achieve perfect short circuit test.

3. Resistance production: Use manual sliding measurement for 1-9 mΩ, superimpose 10-90 mΩ, and adjust freely by clicking on the computer or touch screen;

4. Resistor selection: nickel-chromium alloy, which has the advantages of good heat resistance, small coefficient of change at high temperatures, cheap price, high hardness and large overcurrent. Compared with constantan, it has disadvantages due to high hardness, easy bending and high humidity environment (80 % or more) oxidation rate is faster;

5. Using a shunt to directly divide the voltage for collection, compared with Hall collection (0.2%), the accuracy is higher, because Hall collection uses the inductance generated by the inductor coil to calculate the current, and the capture accuracy is not enough when an instant occurs.

Standard

GB/T38031-2020 Electric vehicle power battery safety requirements

GB36276-2023 Lithium-ion batteries for power energy storage

GB/T 31485-2015 Electric vehicle battery safety requirements and test methods

GB/T 31467.3-2015 Lithium-ion power battery packs and systems for electric vehicles Part 3: Safety requirements and test methods.

Features

| High Current Contactor | Rated working current 4000A, current resistance for more than 10 minutes, using vacuum arc extinguishing system;Can carry maximum instantaneous short-circuit current 10000A; |

| The contact resistance is low and the response speed is fast; | |

| The contactor action is reliable, safe, long life, and easy to maintain; | |

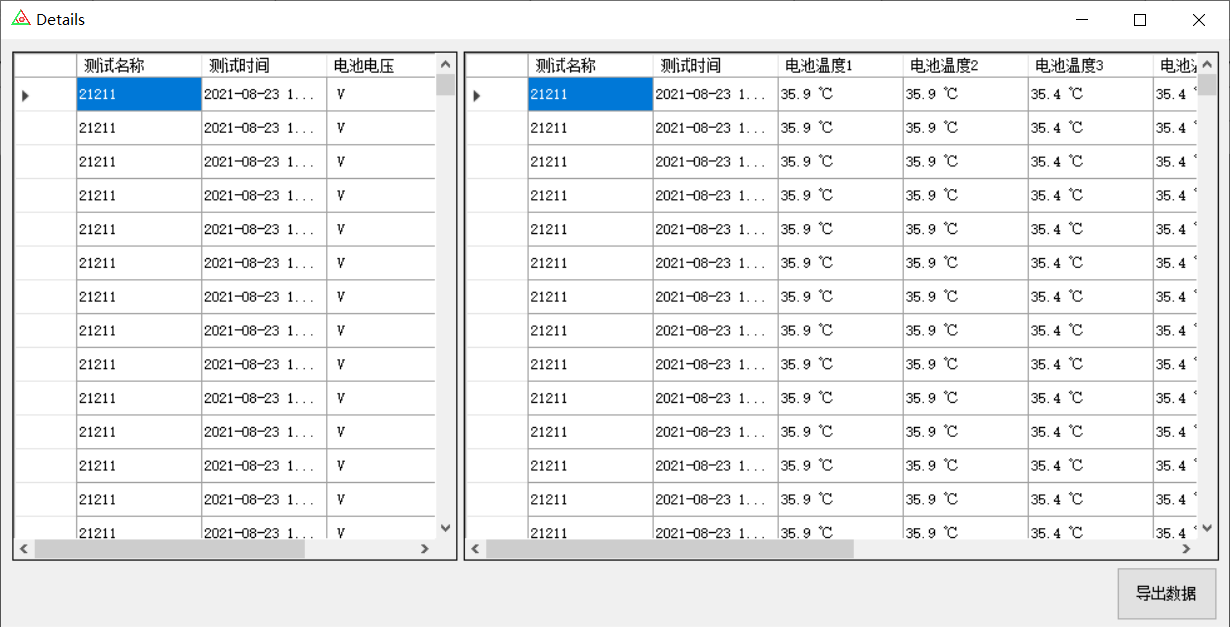

| Current Collection | Measuring current: 0~10000A |

| Acquisition accuracy: ±0.05% FS | |

| Resolution: 1A | |

| Acquisition rate: 1000Hz | |

| Collection channel: 1 channel | |

| Current Collection | Measuring voltage: 0~300V |

| Acquisition accuracy: ±0.1% | |

| Acquisition rate: 1000Hz | |

| Channel: 2 channels | |

| Temperature Range | Temperature range: 0-1000℃ |

| Resolution: 0.1℃ | |

| Collection accuracy: ±2.0℃ | |

| Acquisition rate: 1000Hz | |

| Channel: 10 channels | |

| Control Method | PLC touch screen + computer remote control; |

| Shunt Accuracy | 0.1%FS; |