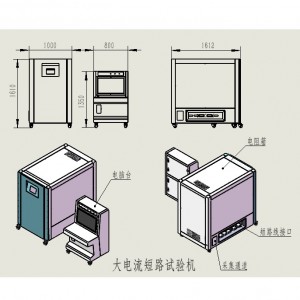

Thermal Abuse Test Chamber

Application

Thermal Abuse Test Chamber:

Thermal Abuse Test Chamber (thermal shock) series equipment is a variety of high temperature impact test, baking, aging test, one of the commonly used equipment, suitable for electronic instruments and meters, materials, electricians, vehicles, metal, electronic products, all kinds of electronic components in the temperature environment, the performance of the index and quality control

Use touch screen controller, high-end atmosphere, powerful function, single point temperature control or program temperature control mode

Casters are installed at the bottom, which can be moved according to the position

PT100 thermal resistance temperature sensor, high precision, fast temperature sensing, high temperature resistance, low maintenance

Users can meet the special requirements of the laboratory according to the processing type of internal and external chamber wall

The outer box is made of cold rolled steel plate, sprayed with paint, corrosion-resistant and high-temperature resistant, and the structure is perfect

The inner box adopts 304# mirror plate, with smooth surface, corrosion resistance and high temperature resistance, easy to clean and easy to maintain

Can be customized to any size, use does not waste space

Specification

|

Box structure |

Inner box size | 500(width)×500(depth)×500(height)mm |

| Outer box size | about 870(width)×720(depth)×1370(height)mm, based on the material as the standard | |

| Control panel | The control panel is installed above the machine | |

| Opening way | Single door opens from right to left | |

| Window | with window on the door, specification W200*H250mm | |

| Inner box material | 430# mirror plate, 1.0mm thick | |

| Material of outer box | cold rolled steel plate, 1.0mm thick. Powder baking paint treatment | |

| Interlayer | two layers can be adjusted, the bottom up to 100mm the first layer, the above equal, with two mesh board | |

| Insulation material | high temperature resistant rock wool, good insulation effect | |

| Sealing material | high temperature foamed silicone strip | |

| Test hole | a test hole is opened on the right side of the machine with a diameter of 50mm | |

| Casters | The machine has movable casters and adjustable fixed foot cups for easy movement and fixed position | |

|

Temperature control system |

Controller | The temperature controller is a touch screen, the fixed value or program operation can be used to control the temperature, can be automatically calculated, PV/SV display at the same time, touch setting. |

| Timing function | built-in timing function, temperature to timing, time to stop heating, while alarm prompt | |

| Data port | computer connection port RS232 interface | |

| Curve | The operating temperature curve can be viewed on the touch screen table | |

| Temperature sensor | PT100 high temperature type | |

| Control output signal | 3-32V | |

| Heating controller | solid state relay SSR without contact | |

| Heating material | high temperature resistant adder | |

| Temperature range | room temperature +20 ~ 200℃ temperature adjustable | |

| Heating rate | 5℃±2.0/min using program time to control the heating rate | |

| Control accuracy | ±0.5℃ | |

| Display accuracy | 0.1℃ | |

| Test temperature | 130℃±2.0℃ (no load test) | |

| Temperature deviation | ±2.0℃ (130℃/150℃) (no load test) | |

|

Air supply system |

Air supply mode | internal hot air circulation, the left side of the inner box air out, the right side return air |

| Motor | long axis high temperature resistant special type, 370W/220V | |

| Fan | multi-wing turbine type 9 inches | |

| Air inlet and outlet | one air inlet on the right and one air outlet on the left | |

|

Protection system |

Overtemperature protection system | when the temperature is out of control and exceeds the set temperature of the overtemperature protector, the heating and power supply will be stopped automatically, so as to protect the safety of products and machines |

| Circuit protection | ground protection, fast safety, overload protection, circuit breaker, etc | |

| Pressure relief device | an explosionproof pressure relief port is opened at the back of the inner box. When the battery explodes, the shock wave generated immediately is discharged, which effectively protects the safety of the machine. Specifications W200*H200mm | |

| Protective device on the door | explosion-proof chain is installed at the four corners of the door to prevent the door from falling off and flying out to damage property and personnel safety in case of explosion | |

| Power supply | voltage AC220V/50Hz single-phase current 16A total power 3.5KW | |

| Weight | about 150KG | |