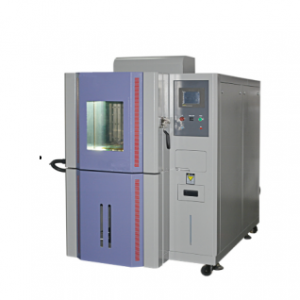

Highly Accelerated Stress Testing (HAST) is a highly effective test method designed to evaluate the reliability and lifetime of electronic products. The method simulates the stresses that electronic products may experience over a long period of time by subjecting them to extreme environmental conditions – such as high temperatures, high humidity and high pressure – for a very short period of time. This testing not only accelerates the discovery of possible defects and weaknesses, but also helps to identify and resolve potential problems before the product is delivered, thus improving the overall quality of the product and user satisfaction.

Test Objects: Chips, motherboards and mobile phones and tablets applying highly accelerated stress to stimulate problems.

1. Adopting imported high-temperature resistant solenoid valve dual-channel structure, to the greatest extent possible to reduce the use of the failure rate.

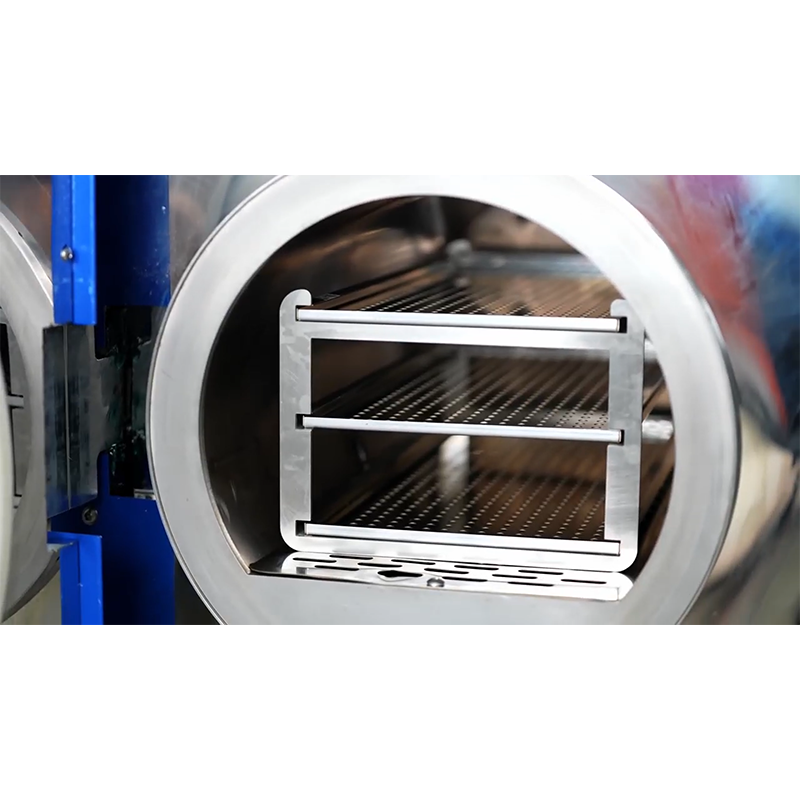

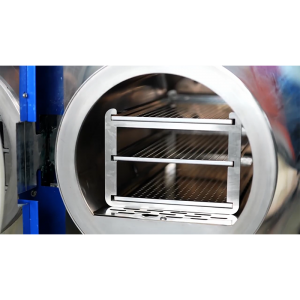

2. Independent steam generating room, to avoid direct impact of steam on the product, so as not to cause local damage to the product.

3. Door lock saving structure, to solve the first generation of products disc type handle locking difficult shortcomings.

4. Exhaust cold air before the test; test in the exhaust cold air design (test barrel air discharge) to improve pressure stability, reproducibility.

5. Ultra-long experimental running time, long experimental machine running 999 hours.

6. Water level protection, through the test chamber water level Sensor detection protection.

7. Water supply: automatic water supply, the equipment comes with a water tank, and not exposed to ensure that the water source is not contaminated.