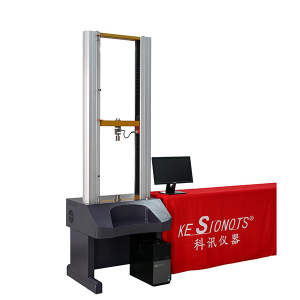

Falling ball impact testing machine

Main uses

Plastic glasses ceramic plate impact resistance testing machine

1. The falling ball weight has multiple specifications and the height is adjustable to meet the requirements of different samples.

2. The sample is clamped and released pneumatically to conduct test operations more quickly and accurately.

3. Foot pedal start switch mode, humanized operation.

4. The steel ball is electromagnetically sucked and released automatically, effectively avoiding system errors caused by human factors.

5. Protective devices make the test process safer.

6. Central positioning device, reliable test results.

Parameter

| Model | KS-FBT |

| Drop ball drop height | 0-2000mm Adjustable |

| Falling ball control method | DC electromagnetic control |

| Steel ball weight | 55g, 64g, 110g, 255g, 535g |

| Power supply | 220V/50HZ, 2A |

| Machine size | About 50*50*220cm |

| Machine weight | About 15kg |

Advantage

Steel ball drop impact testing machine

1. Control panel, intuitive control, already operated;

2. Ball drop device uses infrared rays to align the position;

3. Electromagnet controls falling;

4. Comes with 5 types of steel balls as standard, with a drop height of 2 meters.

Operating instructions

Falling Ball Impact Tester Manufacturers

1. Clamp the sample and use a universal clamp to clamp the sample according to the shape of the sample and the height to which it needs to be dropped (whether the sample needs to be clamped by a clamp and the style of the clamp are determined according to the customer's needs).

2. Start setting the test stroke. Loosen the fixed handle on the electromagnet rod with your left hand, move the bottom end of the electromagnet fixed rod to a position 4cm greater than the required drop height, and then tighten the fixed handle slightly to attract the required steel ball. on the electromagnet.

3. Place one end of the equipped right-angle ruler perpendicular to the scale mark of the required height on the drop pole. Make a slight movement to make the lower end of the steel ball perpendicular to the scale mark of the required height, and then tighten the fixed handle.

4. Start the test, press the drop button, the steel ball will fall freely and impact the test sample. According to the needs of the customer, the test can be repeated and the steel ball test or product test can be replaced, etc., and the test results of each time should be recorded.