-

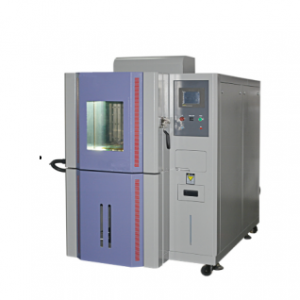

Constant temperature and humidity testers

Constant temperature and humidity test chamber, also known as environmental test chamber, test a variety of materials heat resistance, cold resistance, dry resistance, moisture resistance performance. It is suitable for testing the quality of electronic, electrical, communication, instrumentation, vehicles, plastic products, metal, food, chemical, building materials, medical, aerospace and other products.

-

Universal Salt Spray Tester

This product is suitable for parts, electronic components, protective layer of metal materials and salt spray corrosion test of industrial products. Widely used in electricians, electronic equipment, electronic components, electronics, home appliances hardware accessories, metal materials, paint products and other industries.

-

IP3.4 rain test chamber

1. Advanced factory, leading technology

2. Reliability and applicability

3. Environmental protection and energy saving

4. Humanization and automated system network management

5. Timely and perfect after-sales service system with long-term guarantee.

-

Low Temperature Thermostatic Bath

1. Advanced factory, leading technology

2. Reliability and applicability

3. Environmental protection and energy saving

4. Humanization and automated system network management

5. Timely and perfect after-sales service system with long-term guarantee.

-

80L Constant Temperature and Humidity Chamber

80L Constant Temperature and Humidity Chamber can be used to simulate and maintain specific temperature and humidity environments for testing and storage of various materials, products and samples. It is widely used for product development, quality control and storage tests in the fields of pharmaceuticals, food, materials, biology and medicine.

-

HAST Accelerated Stress Test Chamber

Highly Accelerated Stress Testing (HAST) is a highly effective test method designed to evaluate the reliability and lifetime of electronic products. The method simulates the stresses that electronic products may experience over a long period of time by subjecting them to extreme environmental conditions – such as high temperatures, high humidity and high pressure – for a very short period of time. This testing not only accelerates the discovery of possible defects and weaknesses, but also helps to identify and resolve potential problems before the product is delivered, thus improving the overall quality of the product and user satisfaction.

Test Objects: Chips, motherboards and mobile phones and tablets applying highly accelerated stress to stimulate problems.

1. Adopting imported high-temperature resistant solenoid valve dual-channel structure, to the greatest extent possible to reduce the use of the failure rate.

2. Independent steam generating room, to avoid direct impact of steam on the product, so as not to cause local damage to the product.

3. Door lock saving structure, to solve the first generation of products disc type handle locking difficult shortcomings.

4. Exhaust cold air before the test; test in the exhaust cold air design (test barrel air discharge) to improve pressure stability, reproducibility.

5. Ultra-long experimental running time, long experimental machine running 999 hours.

6. Water level protection, through the test chamber water level Sensor detection protection.

7. Water supply: automatic water supply, the equipment comes with a water tank, and not exposed to ensure that the water source is not contaminated.

-

Walk-in Constant Temperature and Humidity Room

The outer frame structure of this equipment is made of double-sided colour steel heat preservation library board combination, the size of which is ordered according to the customer’s requirements, and is configured according to different requirements. The aging room is mainly composed of box, control system, wind circulation system, heating system, time control system, test load and so on.

-

Anti-yellowing Aging Chamber

Ageing: This machine is used to promote the deterioration of sulphur-added rubber in order to calculate the rate of change in tensile strength and elongation before and after heating. It is generally accepted that one day of testing at 70°C is theoretically equivalent to 6 months of exposure to the atmosphere.

Yellowing Resistance: This machine is simulated in an atmospheric environment, exposed to UV rays of the sun, and changes in appearance are generally considered to be tested at 50°C for 9 hours. Theoretically equivalent to 6 months of exposure to the atmosphere.

Note: Two types of tests can be done. ( Aging and Yellowing Resistance )

-

High Temperature High Pressure Jet Test Machine

The main purpose of this equipment is for vehicles such as buses, buses, lamps, motorbikes and their components. Under the cleaning process conditions of high pressure/steam jet cleaning, the physical and other relevant properties of the product are tested. After the test, the performance of the product is judged to be up to the requirements through calibration, so that the product can be used for design, improvement, calibration and factory inspection.

-

Rapid Humidity and Heat Test Chamber

Rapid Temperature Change Test Chambers are used to determine the suitability of products for storage, transport and use in climatic environments with rapid or slow changes in temperature and humidity.

The test process is based on a cycle of room temperature → low temperature → low temperature dwell → high temperature → high temperature dwell → room temperature. The severity of the temperature cycle test is determined by the high/low temperature range, the dwell time and the number of cycles.

Rapid Temperature Change Chamber is a test equipment used to simulate and test the performance and reliability of materials, electronic components, products, etc. in a rapid temperature change environment. It can rapidly change the temperature in a relatively short period of time to assess the stability, reliability and performance changes of samples at different temperatures.

-

Battery High/low Temperature Test Machine KS-HD36L-1000L

1、Advanced factory, leading technology

2、Reliability and applicability

3、Environmental protection and energy saving

4、Humanization and automated system network management

5、Timely and perfect after-sales service system with long-term guarantee.

-

36L Constant Temperature and Humidity Chamber

Constant temperature and humidity chamber is a kind of test equipment to simulate and maintain a constant temperature and humidity environment, which is widely used in various fields of product research and development, quality control and preservation tests. It is capable of providing stable environmental conditions for the test specimen within the set temperature and humidity range.

Environment

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

-

Top