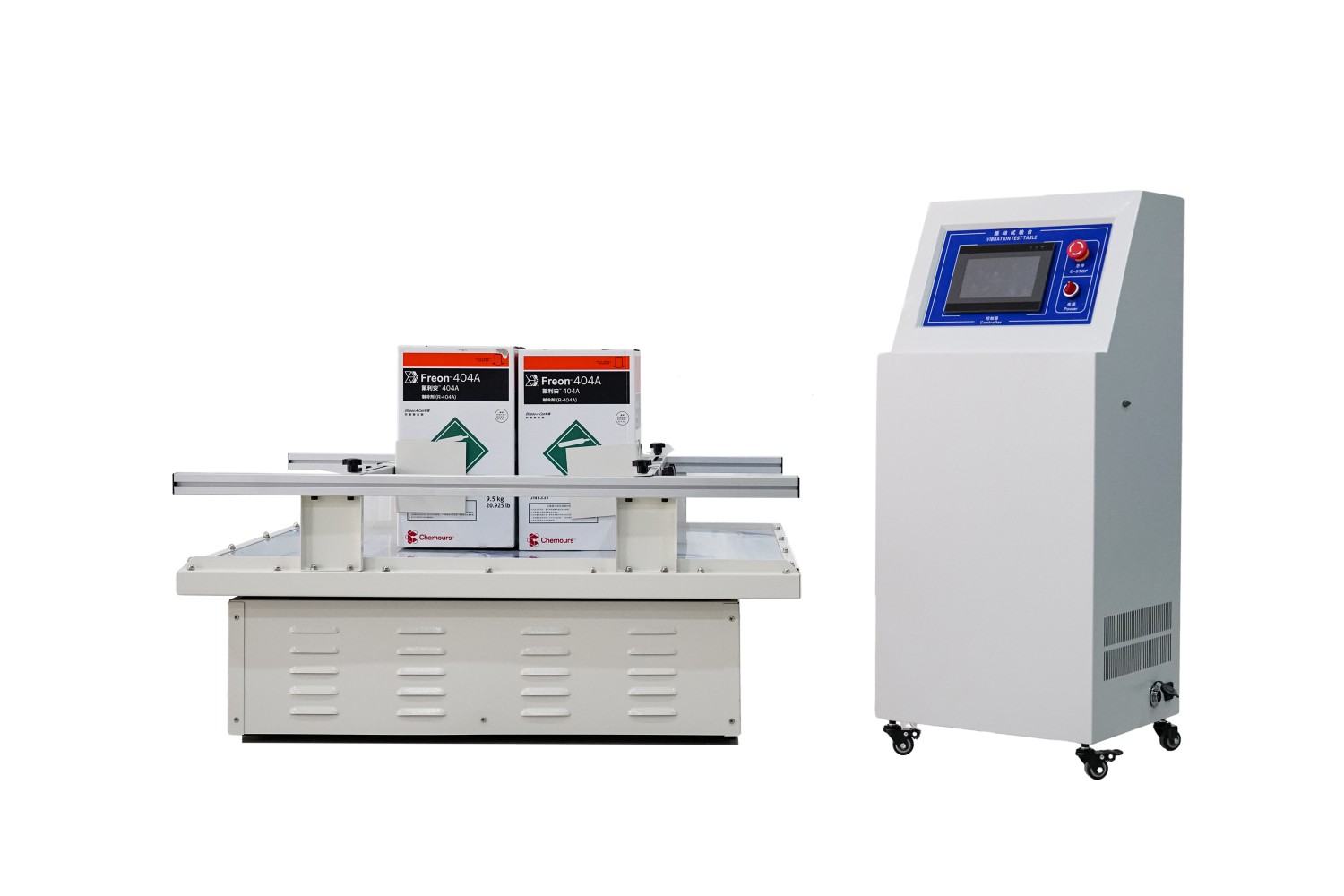

Easy to operate vibration test bench

Application

The simulated transportation vibration table, also known as a "vibration table", is used to replicate the damage caused by bumps during road transportation. Its purpose is to determine whether a product can withstand environmental vibration. The simulated automobile transportation vibration test bench assesses the ability of various items with specific loads to withstand actual road conditions during automobile transportation. This allows for the evaluation of the impact of actual conditions on the item in a laboratory setting, providing a basis for the evaluation or confirmation of goods and their packaging. This testing machine is a valuable tool for improving product quality and reliability.

The internationally advanced distributed system mechanism system with32-bit floating point DSP processor is used. The technical performance of the vibration control system is further improved. Modular and low noise

design technology, independent installation in the control box, simple connection with USB 2.0 and computer, Windows 8 based application software, powerful control software with adaptive control algorithms.

High precision-microcomputer numerical control timing; digital display vibration rate monitoring.

Extremely low noise - synchronized quiet belt rotation; DC motor buffer start; vibration avoidance rubber feet.

Easy to operate - Aluminum profile slide rail clamping.

Easy to install and dismantle-heavy duty steel chassis with vibration damping rubber bottom pad, the whole machine does not need to be fixed, smooth operation.

Low price - about one-fifth of the price of similar equipment in other countries.

| Direction of vibration | Rotary (Runner) |

| Maximum test load | 200kg |

| Vibration frequency (rpm) | 100~300RPM continuously adjustable |

| amplification | 1 inch (25.4 mm) ± 1.5% |

| counters | 0~999.99h |

| Size of working table | LxW(mm):1400x1000mm |

| weights | About 580kg |

| power supply | 1∮,AC220V,10A |

| Operating time setting range | 0~99H99/ 0~99M99/ 0~99S99 |

| Shaker Material | Stainless steel |

| fixture (machining) | Aluminum |

| Digital speed accuracy | Not more than ±3 rpm |