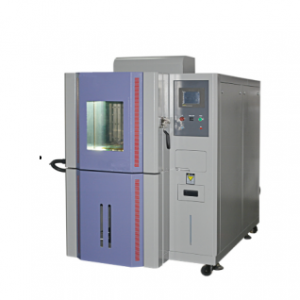

Thermal Shock Test Chamber

Application

Thermal Shock Test Chambers are advanced testing equipment that assesses the chemical changes and physical damage caused by the thermal expansion and contraction of materials or composites. These chambers subject the test specimens to extreme high and low temperatures in the shortest time possible, simulating the effects of rapid temperature changes in real-world environments. Designed for a wide range of materials including metals, plastics, rubber, electronics, and more, these test chambers provide valuable insights for product improvement and quality control. By exposing the materials to rapid and extreme temperature cycling, any weaknesses or vulnerabilities can be identified and addressed before they affect the product's performance or durability.

Parameter

| Machine type |

50 |

80 |

100 |

50 |

80 |

150 |

50 |

80 |

100 |

||||

|

Air-cooled |

Air-cooled |

Water-cooled |

Air-cooled |

Water cooled |

Water cooled |

Water cooled |

Water cooled |

Water cooled |

|||||

|

KS-LR80A |

KS-LR80B |

KS-LR80C |

|||||||||||

| High temperature setting |

+60℃~+150℃ |

+60℃~+150℃ |

+60℃~+150℃ |

||||||||||

| Low temperature setting |

-50℃~-10℃ |

-55℃~-10℃ |

-60℃~-10℃ |

||||||||||

| High temperature bath temperature setting range |

+60℃~+180℃ |

+60℃~+200℃ |

+60℃~+200℃ |

||||||||||

| Low temperature bath temperature setting range |

-50℃~-10℃ |

-70℃~-10℃ |

-70℃~-10℃ |

||||||||||

| Shock recovery time | -40℃~+150℃ -40°C to +150°C approx. 5 minutes |

-55℃~+150℃ -55°C to +150°C approx. 5 minutes |

-60℃~+150℃ -60°C to +150°C approx. 5 minutes |

||||||||||

| High & Low Temperature Shock Constant Time |

Over 30 minutes |

||||||||||||

| Temperature recovery performance |

30min |

||||||||||||

| Load (Plastic IC) |

5KG 7.5KG 15KG |

5KG 7.5KG 15KG |

2.5KG 5KG 7.5KG |

||||||||||

| Compressor Selection |

Tecumseh or German BITZER (optional) |

||||||||||||

| Temperature Fluctuation |

±0.5℃ |

||||||||||||

| Temperature Deviation |

≦±2℃ |

||||||||||||

| Size |

Internal dimensions |

External dimensions |

|||||||||||

| (50L) Volume (50L) |

36×40×55 (W × H × D)CM |

146×175×150(W × H × D)CM |

|||||||||||

| (80L) Volume (80L) |

40×50×40 (W × H × D)CM |

155×185×170(W × H × D)CM |

|||||||||||

| (100L) Volume (100L) |

50×50×40 (W × H × D)CM |

165×185×150(W × H × D)CM |

|||||||||||

| (150L) Volume (150L) |

60*50*50 (W × H × D)CM |

140*186*180(W × H × D)CM |

|||||||||||

| Power and net weight |

50L |

80L |

100L~150L |

||||||||||

| Model |

D-A |

D-B |

D-C |

D-A |

D-B |

D-C |

D-A |

D-B |

D-C |

||||

| KW |

17.5 |

19.5 |

21.5 |

18.5 |

20.5 |

23.5 |

21.5 |

24.5 |

27 |

||||

| KG |

850 |

900 |

950 |

900 |

950 |

1000 |

1050 |

1150 |

1250 |

||||

| Voltage | (1)AC380V 50Hz AC 380V 50Hz three-phase four-wire + protective earth | ||||||||||||