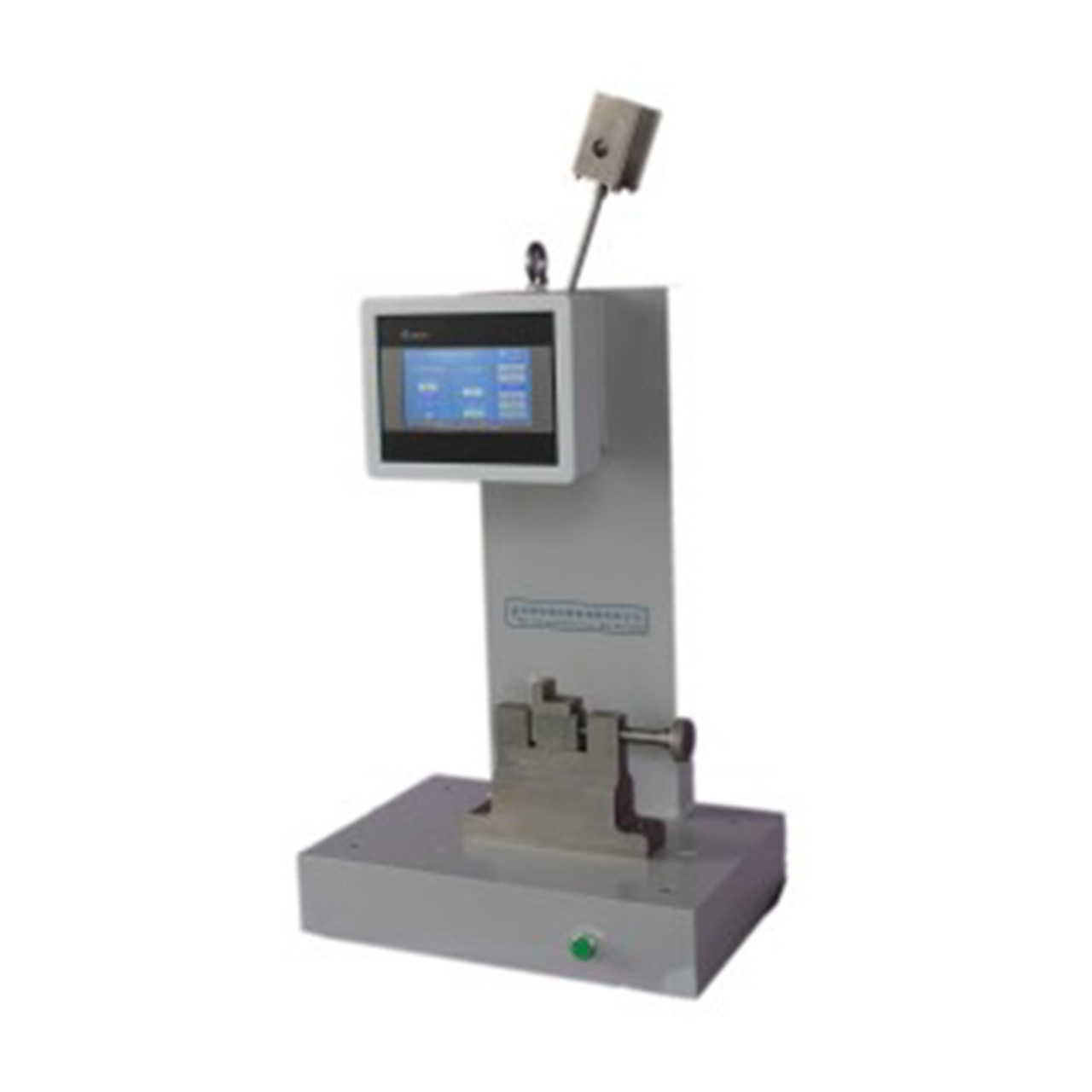

Cantilever beam impact testing machine

Technical Parameters

| Model | KS-6004B |

| Impact speed | 3.5m/s |

| Pendulum energy | 2.75J, 5.5J, 11J, 22J |

| Pendulum pre-lift angle | 150° |

| Strike center distance | 0.335m |

| Pendulum torque | T2.75=1.47372Nm T5.5=2.94744Nm

T11=5.8949Nm T22=11.7898Nm |

| The distance from the impact blade to the top of the jaw | 22mm±0.2mm |

| Blade fillet radius | Blade fillet radius |

| Angle measurement accuracy | 0.2 degrees |

| Energy calculation | Grades: 4 grades

Method: Energy E = potential energy - loss Accuracy: 0.05% of indication |

| Energy units | J, kgmm, kgcm, kgm, lbft, lbin interchangeable |

| Temperature | -10℃~40℃ |

| Power supply | Power supply |

| Sample type | The sample type complies with the requirements of GB1843 and ISO180 standards |

| Overall dimensions | 50mm*400mm*900mm |

| Weight | 180kg |

Experiment Method

1. Measure the test thickness according to the machine shape, measure a point at the center of all samples, and take the arithmetic mean of the 10 sample tests.

2. Select the punch according to the required anti-pendulum impact energy of the test so that the reading is between 10% and 90% of the full scale.

3. Calibrate the instrument according to the instrument usage rules.

4. Flatten the sample and place it in the holder to clamp it. There should be no wrinkles or excessive tension around the sample. The impact surfaces of the 10 specimens should be consistent.

5. Hang the pendulum on the release device, press the button on the computer to start the test, and make the pendulum impact the sample. Perform 10 tests in the same steps. After the test, the arithmetic mean of the 10 samples is automatically calculated.

Auxiliary Structure

1. sealing: double-layer high-temperature resistant high tensile seal between the door and the box to ensure the airtightness of the test area;

2. door handle: the use of non-reaction door handle, easier to operate;

3. casters: the bottom of the machine adopts high quality fixed PU movable wheels;

4. Vertical body, hot and cold boxes, using the basket to convert the experimental area where the test product, to achieve the purpose of the hot and cold shock test.

5. This structure minimizes the heat load when the hot and cold shock, shorten the temperature response time, is also the most reliable, the most energy efficient way of cold executive shock.