Battery heavy impact tester

Application

After filling the battery according to the specified test method, place the battery on the surface of the platform. Place a metal rod with a diameter of 15.8mm±0.2mm horizontally on the surface of the battery at its geometric center. Use a weight of 9.1kg±0.1kg to freely fall from a height of 610mm±25mm and impact the surface of the battery with the metal rod, and observe for 6 hours. For cylindrical batteries, the longitudinal axis should be parallel to the surface of the weight during the impact test, and the metal rod should be perpendicular to the longitudinal axis of the battery. For square batteries and pouch batteries, only the wide surface is subjected to the impact test. For button batteries, the metal rod should span across the center of the battery surface during the impact test. Each sample is only subjected to one impact test.

Acceptance criteria: The battery should not catch fire or explode.

Auxiliary Structure

| dropout weight | 9.1kg±0.1kg |

| Impact Height | 0~1000mm adjustable |

| altitude display | Display via controller, accurate to 1mm |

| altitude error | ±5mm |

| Impact mode | Lift the ball to a certain height and release it, the ball falls freely in the vertical direction without tilting or swaying |

| Display Mode | PLC touch screen display of parameter values |

| bar diameter | a 15.8 ± 0.2 mm (5/8 inch) steel rod (placed vertically across the centre of the cell, with a weight falling on the rod and the rod remaining parallel to the bottom surface of the square cell). |

| Inner box material | SUS#304 stainless steel plate, thickness 1mm, 1/3 with Teflon fusion tape, high temperature resistance, corrosion resistance, insulation and easy to clean. |

| Outer case material | Cold rolled plate with lacquered finish, thickness 1.5mm |

| exhaust vent | Located at the back of the box, with a diameter of 150mm, the external diameter of the exhaust duct is convenient for connecting to a high-power laboratory extractor fan; |

| box door | Single door, double doors, open tempered glass observation window, cold pull handle door locks, the box door plus silicone foam compression strip; |

| upper and lower impact surfaces | Stainless steel plate |

| visual window | 250mm*200mm |

| Lifting method | Electric lift |

| Using the power supply | 1∮,AC220V, 3A |

| power supply | 700W |

| Weight (approx.) | Approx. 250kg |

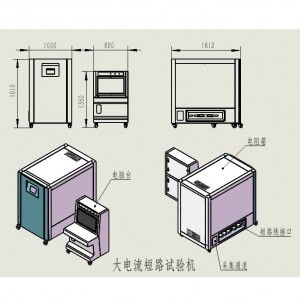

| Battery Heavy Impact Tester (with Monitor) | |