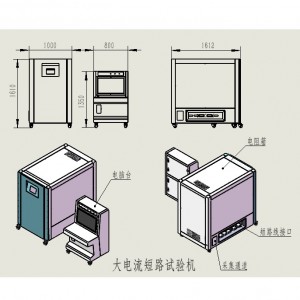

Battery explosion-proof test chamber

Application

The battery explosion-proof test box is mainly used for overcharging, overdischarging, or short-circuit testing of batteries. The batteries are placed in the explosion-proof box and connected to a charge-discharge tester or short-circuit testing machine. This provides protection for the operators and instruments. The design of the test box can be customized according to the testing requirements.

Application

| standard | Indicator parameters |

| Inner box size | W1000*D1000*H1000mm (can be customised) |

| External Dimension | Approx. W1250*D1200*H1650mm |

| control panel | Control panel on top of the machine |

| Inner box material | 201# Stainless steel sanding plate thickness 3.0mm |

| Outer case material | A3 Cold plate lacquered thickness 1.2 mm |

| Door opening method | Single door opening from right to left |

| viewing window | Door with visible window, size W250*350mm, with protective mesh on the glass. |

| lagging | The inner box is empty, the bottom of the configuration of a marble plate and the box body inside 3/1 place affixed with Teflon foot paper, corrosion resistance and flame retardant performance, convenient cleaning |

| test hole | The left and right sides of the machine are open to electrical test holes 2, hole diameter 50mm, convenient to put a variety of temperature, voltage, current collection line |

| louvre | One air outlet DN89mm on the left and one on the right. |

| caster | The bottom of the machine is installed with brake movable casters, which can be moved arbitrarily. |

| illumination | A light is installed inside the box, which is switched on when needed and switched off when not needed. |

| smoke extraction | Battery testing, the explosion of smoke exhaust can be discharged to the outdoors through the exhaust fan, by the explosion-proof box at the rear of the exhaust pipe pipework to the outdoors, manually activated exhaust . |

| Safety relief devices | Inside the box right after the opening of a pressure relief port, in the event of an explosion, the instantaneous discharge of shock waves, pressure relief port specifications W300 * H300mm (with the function of unloading pressure to unload the explosion) |

| door locks | Installation of explosion-proof chain on the door to prevent the door from coming off in the event of impact, which may cause injury or other damages. |

| smoke detection | Installation of a smoke alarm in the inner box, when the smoke reaches a thick alarm function and at the same time smoke extraction or manual smoke extraction |

| power supply | Voltage AC 220V/50Hz single phase Current 9A Power 1.5KW |

| Circuit protection systems | Ground protection, quick-acting insurance |

| Optional | Fire extinguishing device: the top of the box can be installed to spray carbon dioxide pipeline, such as the battery in the event of an open fire, the fire can be manually activated to extinguish the fire or remote control to start extinguishing |

Write your message here and send it to us